Welcome to this comprehensive guide on Cast 316 Stainless Steel, an indispensable material in the realm of manufacturing and design. In this section, we will outline the purpose and scope of this guide, shed light on the significance of Cast 316 Stainless Steel, and provide an overview of its relevance in the European manufacturing landscape.

Purpose and Scope of the Guide

The purpose of this guide is to offer a deep dive into the world of Cast 316 Stainless Steel—a material renowned for its exceptional properties and versatile applications. Whether you are a manufacturer seeking insights into the benefits of using Cast 316 Stainless Steel or a designer interested in its aesthetic appeal, this guide is tailored to provide valuable information.

The scope of this guide encompasses an array of topics, including the composition and properties of Cast 316 Stainless Steel, its advantages in European manufacturing, quality assurance measures, and the various casting processes employed. We will also explore maintenance tips to ensure the longevity of Cast 316 Stainless Steel products and conclude with key takeaways and future trends in this dynamic field.

Significance of Cast 316 Stainless Steel

Cast 316 Stainless Steel holds a pivotal role in various industries, thanks to its exceptional qualities. Its significance lies in its superior resistance to corrosion, durability in challenging European climates, and its ability to merge functionality with aesthetic appeal. These attributes make it a sought-after choice for manufacturers and designers across Europe.

Overview of the European Manufacturing Landscape

In the European manufacturing landscape, innovation and quality are paramount. Manufacturers in Europe adhere to stringent standards, and materials like Cast 316 Stainless Steel play a vital role in meeting these high expectations. As we explore the applications and benefits of Cast 316 Stainless Steel, we’ll gain a deeper understanding of its integral role in the European manufacturing sector.

Understanding Cast 316 Stainless Steel

In this section, we will delve into the core aspects of Cast 316 Stainless Steel, understanding its composition, properties, and the manifold benefits it brings to European manufacturing.

Composition and Properties

Cast 316 Stainless Steel, often referred to as Grade 316 stainless steel, is a corrosion-resistant alloy renowned for its exceptional composition. It primarily consists of:

- Chromium (Cr): At around 16-18%, chromium provides excellent resistance to corrosion, making Cast 316 Stainless Steel suitable for a wide range of environments, including marine and industrial settings.

- Nickel (Ni): With a nickel content of approximately 10-14%, Cast 316 Stainless Steel exhibits superior toughness and ductility. This enhances its suitability for various manufacturing processes.

- Molybdenum (Mo): The addition of about 2-3% molybdenum enhances the alloy’s resistance to pitting and crevice corrosion, making it ideal for applications involving exposure to chloride environments.

- Iron (Fe): As the base metal, iron provides structural integrity and robustness to the alloy.

These components, when combined, create a stainless steel alloy with exceptional corrosion resistance, high-temperature tolerance, and superb mechanical properties.

Benefits in European Manufacturing

Cast 316 Stainless Steel offers a multitude of benefits that make it a preferred choice in European manufacturing:

- Corrosion Resistance: In the diverse climates of Europe, where exposure to moisture and varying temperatures is common, Cast 316 Stainless Steel excels in resisting corrosion. This is particularly crucial for outdoor structures, marine equipment, and industrial machinery.

- Durability and Longevity: Cast 316 Stainless Steel products have a longer lifespan due to their resistance to corrosion, wear, and tear. This durability is particularly valuable in Europe’s demanding industrial applications.

- Aesthetic Appeal for European Design: Beyond its functional advantages, the alloy’s aesthetic appeal makes it a preferred choice in European architectural and design applications. Its lustrous finish and timeless appearance complement modern and traditional design aesthetics alike.

Applications and Industries

Cast 316 Stainless Steel finds extensive applications in a wide range of European industries, including:

- Marine Industry: From shipbuilding to offshore platforms, Cast 316 Stainless Steel is a staple material due to its resistance to saltwater corrosion.

- Food and Beverage: Its hygienic properties and corrosion resistance make it ideal for equipment used in food processing and storage.

- Chemical Processing: The alloy’s resistance to chemical corrosion makes it invaluable in chemical and pharmaceutical industries.

- Construction and Architecture: In Europe’s construction and architectural sectors, Cast 316 Stainless Steel is used for structural components, facades, and decorative elements.

Quality Assurance in Cast 316 Stainless Steel

Ensuring the highest quality standards for Cast 316 Stainless Steel is of paramount importance, especially in European manufacturing where precision and reliability are non-negotiable. In this section, we will explore the rigorous quality assurance measures that govern the production of Cast 316 Stainless Steel, including manufacturing standards and certifications, quality control procedures, and European regulatory compliance.

Manufacturing Standards and Certifications

Cast 316 Stainless Steel adheres to stringent manufacturing standards and certifications to guarantee its quality and reliability. Key standards and certifications include:

- ASTM A351/A351M: This standard outlines the requirements for castings made of austenitic stainless steel, including Grade 316. Compliance with ASTM A351/A351M ensures that the material meets the specified chemical composition and mechanical properties.

- EN 10283: In Europe, EN 10283 sets the standards for corrosion-resistant steel castings, including those made from Cast 316 Stainless Steel. This standard ensures that the material is suitable for various European applications.

- ISO 9001:2015: Manufacturers often seek ISO 9001:2015 certification, demonstrating their commitment to quality management systems. This certification ensures that manufacturing processes are consistent and adhere to high-quality standards.

Quality Control Measures

Quality control measures are implemented at every stage of the manufacturing process to maintain the integrity of Cast 316 Stainless Steel. These measures include:

- Material Testing: Rigorous material testing is conducted to verify compliance with chemical composition and mechanical properties. This includes chemical analysis, tensile testing, and hardness testing.

- Dimensional Checks: Castings are subject to precise dimensional checks to ensure they meet specified tolerances and dimensions.

- Non-Destructive Testing (NDT): Techniques such as radiographic testing, ultrasonic testing, and dye penetrant testing are employed to detect any internal defects that could compromise the integrity of the casting.

European Regulatory Compliance

Compliance with European regulations is crucial for the use of Cast 316 Stainless Steel in various applications. Manufacturers must ensure that their products meet specific European directives, such as:

- REACH: Compliance with the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation ensures that the alloy’s chemical composition meets environmental and safety standards.

- CE Marking: In cases where Cast 316 Stainless Steel products are used in construction or other regulated industries, CE marking is often required to demonstrate conformity with European health, safety, and environmental protection standards.

By adhering to these stringent quality assurance measures and regulatory requirements, manufacturers ensure that Cast 316 Stainless Steel maintains its reputation as a reliable and high-quality material for European manufacturing.

Advantages of Cast 316 Stainless Steel

Cast 316 Stainless Steel boasts a remarkable set of advantages that make it an exceptional choice for a wide range of applications, especially in European climates. In this section, we will explore the specific advantages that set Cast 316 Stainless Steel apart, including its corrosion resistance in European climates, durability and longevity, and its aesthetic appeal for European design.

Corrosion Resistance in European Climates

One of the standout qualities of Cast 316 Stainless Steel is its unparalleled resistance to corrosion, a crucial attribute given the diverse and often challenging climates across Europe. Here’s how this alloy excels:

- Resistance to Pitting and Crevice Corrosion: In coastal regions or areas with high humidity, pitting and crevice corrosion can be a significant concern. Cast 316 Stainless Steel’s molybdenum content provides excellent resistance to these types of localized corrosion, ensuring the integrity of structures and equipment.

- Chloride Resistance: European environments, particularly near industrial zones and bodies of water, often contain chloride ions that can accelerate corrosion. Cast 316 Stainless Steel’s composition makes it highly resistant to chloride-induced corrosion, making it a reliable choice for marine and industrial applications.

- Acid Resistance: In industrial settings where exposure to acids is common, this alloy maintains its corrosion resistance. This attribute is essential for equipment used in chemical processing and wastewater treatment plants.

Durability and Longevity

The durability and longevity of Cast 316 Stainless Steel are two additional key advantages, particularly in the context of European manufacturing:

- Long Lifespan: Products and structures made from Cast 316 Stainless Steel have a significantly extended lifespan compared to other materials. This longevity translates to cost savings over time and reduced maintenance requirements.

- Low Maintenance: The material’s resistance to corrosion and staining minimizes the need for extensive maintenance. This is especially advantageous in European climates, where harsh weather conditions can accelerate wear and tear on materials.

Aesthetic Appeal for European Design

Beyond its functional advantages, Cast 316 Stainless Steel offers an aesthetic appeal that aligns with European design sensibilities:

- Lustrous Finish: The material’s naturally lustrous finish adds a touch of elegance and sophistication to architectural elements and design features. This makes it a preferred choice in European architecture, interior design, and the creation of decorative elements.

- Versatility in Design: Cast 316 Stainless Steel can be shaped and molded to suit a wide range of design requirements. Its versatility allows designers to achieve both modern and traditional aesthetics, enhancing the overall visual appeal of European projects.

As we progress through this guide, we will explore the various casting processes used for Cast 316 Stainless Steel, maintenance and care guidelines to preserve its advantages, and provide key takeaways. In the next section, we will delve into the different casting processes employed to shape this remarkable material into functional and artistic forms.

Casting Processes for 316 Stainless Steel

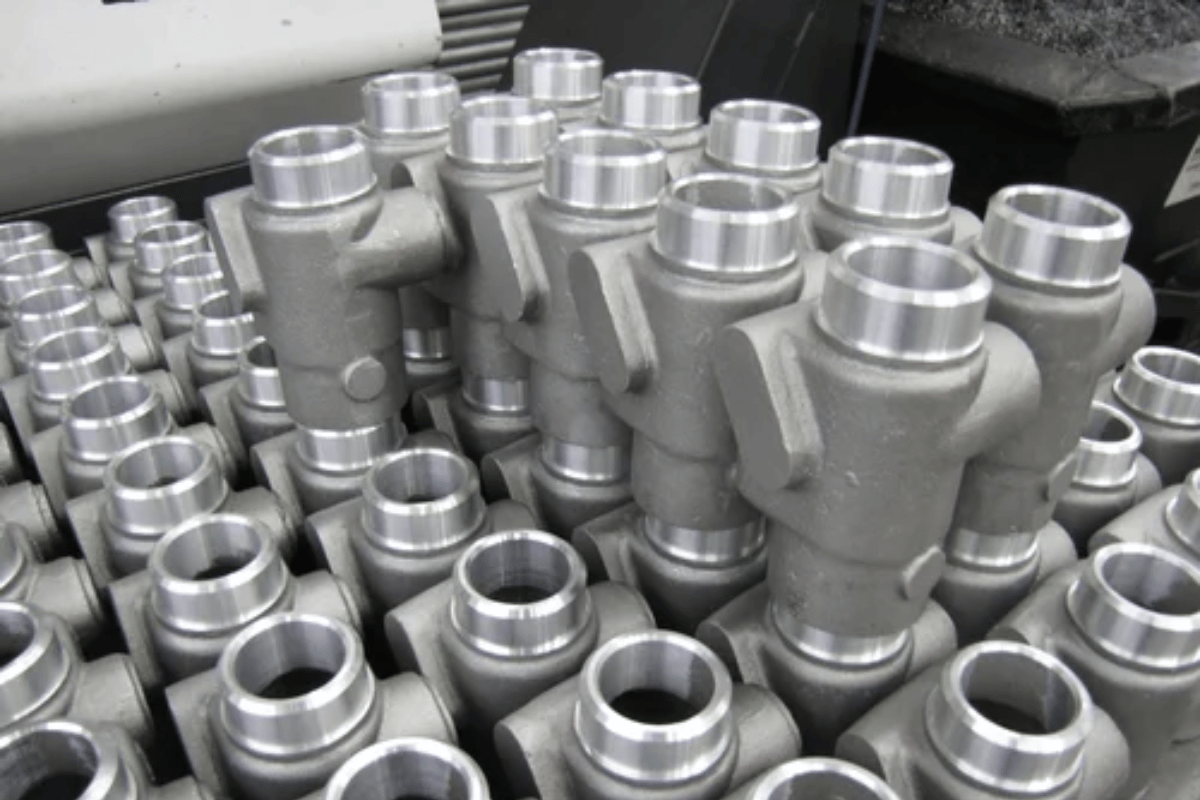

The manufacturing of Cast 316 Stainless Steel products involves several casting processes that allow for the creation of complex and precise components. In this section, we will explore the primary casting methods used for shaping this exceptional material: investment casting, sand casting, and precision machining and finishing.

Investment Casting

Investment casting, also known as precision casting or lost-wax casting, is a highly versatile method employed in the production of intricate and dimensionally accurate Cast 316 Stainless Steel components. The process involves the following key steps:

- Pattern Creation: A detailed wax or resin replica of the desired part, known as the pattern, is created.

- Assembly: Multiple wax patterns are attached to a central wax runner system to form a cluster, resembling a tree.

- Investment: The wax tree is immersed in a ceramic slurry and coated with fine ceramic sand. This creates a ceramic shell around the wax patterns.

- De-waxing: The assembly is heated, causing the wax to melt and drain, leaving behind a hollow mold.

- Casting: Molten Cast 316 Stainless Steel is poured into the ceramic mold, filling the voids left by the wax patterns.

- Cooling and Solidification: The casting cools and solidifies within the mold.

- Shell Removal: The ceramic shell is removed through mechanical or chemical means, revealing the cast component.

Investment casting is favored for its ability to produce complex, high-precision parts with excellent surface finishes. It is widely used in industries where intricate designs and tight tolerances are essential, such as aerospace, automotive, and medical equipment manufacturing.

Sand Casting

Sand casting is another popular method for producing Cast 316 Stainless Steel components, particularly when larger or less intricate parts are required. The sand casting process involves the following steps:

- Pattern Creation: A pattern, typically made of wood, metal, or resin, is used to create a negative impression in a two-part sand mold.

- Mold Preparation: The mold consists of two halves, the cope, and the drag, which are assembled to form a cavity.

- Mold Filling: Molten Cast 316 Stainless Steel is poured into the mold cavity.

- Cooling and Solidification: The casting cools and solidifies within the mold.

- Mold Breakdown: After solidification, the sand mold is broken apart, revealing the cast component.

Sand casting is cost-effective and suitable for a wide range of sizes and shapes. While it may not offer the precision of investment casting, it is a practical choice for many applications, including industrial equipment and machinery components.

Precision Machining and Finishing

Regardless of the casting method used, Cast 316 Stainless Steel components often undergo precision machining and finishing processes to achieve the desired specifications and surface quality. These processes may include:

- Machining: Machining operations such as turning, milling, and grinding are employed to achieve precise dimensions and tolerances.

- Surface Finishing: Techniques like polishing, passivation, and electropolishing are used to enhance the surface finish and remove any surface imperfections.

- Quality Inspection: Comprehensive inspections are conducted to ensure that the final product meets the specified quality standards.

In the subsequent sections of this guide, we will delve into maintenance and care guidelines for Cast 316 Stainless Steel products and provide key takeaways. Next, in Section #6, we will explore essential tips for preserving the longevity and performance of Cast 316 Stainless Steel products.

Maintenance and Care

Preserving the longevity and performance of Cast 316 Stainless Steel products is essential to ensure they continue to deliver on their exceptional qualities. In this section, we will provide valuable tips for maintaining and caring for Cast 316 Stainless Steel, including guidelines for cleaning, maintenance, and European recommendations.

Tips for Preserving Cast 316 Stainless Steel Products

- Regular Cleaning: Periodic cleaning is crucial to remove surface contaminants and maintain the alloy’s lustrous finish. Use a mild detergent or a specialized stainless steel cleaner, followed by rinsing with clean water. Avoid abrasive cleaners or scouring pads that can scratch the surface.

- Avoid Chlorides: While Cast 316 Stainless Steel is highly resistant to chloride-induced corrosion, it’s advisable to minimize exposure to chlorides whenever possible. Rinse off any saltwater residue, especially in marine environments.

- Passivation: Passivation is a chemical process that enhances the corrosion resistance of stainless steel. It is recommended to periodically passivate Cast 316 Stainless Steel components, especially those used in harsh environments or exposed to chemicals.

- Inspect for Damage: Regularly inspect Cast 316 Stainless Steel products for signs of damage, including cracks, dents, or surface corrosion. Promptly address any issues to prevent them from worsening.

- Repairs and Restoration: In the event of damage or surface blemishes, consider professional repairs or restoration services. Skilled technicians can restore the appearance and integrity of the material.

Cleaning and Maintenance Guidelines

To maintain the aesthetic appeal and performance of Cast 316 Stainless Steel products, follow these cleaning and maintenance guidelines:

- Interior Applications: For indoor applications, routine cleaning with a soft cloth or sponge and a mild detergent is usually sufficient. Dry the surface thoroughly after cleaning to prevent water spots.

- Exterior Applications: Exterior applications may require more frequent cleaning due to exposure to environmental elements. Consider a routine cleaning schedule to prevent the buildup of dirt and contaminants.

- Rust Stains: In cases where rust stains occur, use a rust remover specifically formulated for stainless steel. Follow the manufacturer’s instructions carefully.

- Grease and Oil: To remove grease or oil stains, use a specialized stainless steel degreaser. Rinse thoroughly after cleaning.

European Recommendations

In European climates, where exposure to moisture and changing weather conditions is common, adhering to these recommendations is particularly important:

- Saltwater Exposure: For Cast 316 Stainless Steel components in marine environments, rinse with fresh water regularly to remove salt residue. Apply a corrosion inhibitor for added protection.

- Coastal Areas: In coastal regions with high salt content in the air, consider more frequent cleaning and maintenance to prevent corrosion.

- Temperature Fluctuations: Rapid temperature fluctuations can cause condensation on stainless steel surfaces. Ensure proper ventilation and moisture control in indoor environments.

By following these maintenance and care guidelines, you can extend the life of Cast 316 Stainless Steel products, maintain their aesthetic appeal, and ensure their continued performance in European climates.

In the final section of this guide, we will recap the key takeaways and recommendations, as well as explore future trends in the use of Cast 316 Stainless Steel.

How Brittle Is Cast 316 Stainless Steel? Will It Bend Or Break?

Conclusion

In conclusion, we have explored the world of Cast 316 Stainless Steel, a remarkable material renowned for its exceptional properties and versatile applications. This guide has provided valuable insights into the composition and properties of Cast 316 Stainless Steel, its advantages in European manufacturing, quality assurance measures, and the various casting processes involved.

Key Takeaways and Recommendations

Here are the key takeaways and recommendations from our exploration:

- Exceptional Corrosion Resistance: Cast 316 Stainless Steel’s resistance to corrosion, especially in European climates, makes it a reliable choice for a wide range of applications.

- Durability and Longevity: Its durability and extended lifespan reduce maintenance requirements and offer cost savings over time.

- Aesthetic Appeal: The alloy’s lustrous finish and versatility in design make it an attractive choice for European architecture and design projects.

- Quality Assurance: Compliance with manufacturing standards, certifications, and quality control measures ensures the reliability of Cast 316 Stainless Steel products.

- Casting Processes: Investment casting and sand casting are versatile methods for shaping this material into intricate or larger components, respectively.

- Maintenance and Care: Regular cleaning, passivation, and inspections are essential for preserving the performance and appearance of Cast 316 Stainless Steel.

Future Trends in Cast 316 Stainless Steel

Looking ahead, the future trends in the use of Cast 316 Stainless Steel are promising:

- Sustainability: Increasing emphasis on sustainability and environmental responsibility may drive the development of more eco-friendly manufacturing processes for stainless steel.

- Advanced Alloys: Ongoing research may lead to the development of advanced stainless steel alloys with even greater resistance to corrosion and improved mechanical properties.

- Digital Technologies: The integration of digital technologies, such as 3D printing and digital twin simulations, may revolutionize the design and production of stainless steel components.

As the world of manufacturing and design continues to evolve, Cast 316 Stainless Steel will likely remain a material of choice due to its unique blend of corrosion resistance, durability, and aesthetic appeal.

For further inquiries, product specifications, or to explore the possibilities of Cast 316 Stainless Steel in your projects, please reach out to reputable suppliers and manufacturers who specialize in this exceptional material.

Thank you for embarking on this journey of discovery with us, and we hope this guide has been a valuable resource for your understanding of Cast 316 Stainless Steel and its significance in European manufacturing and design.