Welcome to this comprehensive guide on stainless steel casting parts, where we will delve into the world of stainless steel casting and its pivotal role in European markets. In this section, we will outline the purpose and scope of this guide, highlight the significance of stainless steel casting parts in Europe, and provide an overview of the current trends shaping the European manufacturing landscape.

Stainless Steel Casting Parts have emerged as essential components in a wide array of industries, contributing to the development and success of various European businesses. From automotive to aerospace, healthcare to construction, stainless steel casting plays a vital role in ensuring the reliability and performance of critical machinery and structures.

Purpose and Scope of the Guide

Our primary aim with this guide is to offer a comprehensive resource for anyone seeking insights into stainless steel casting parts. Whether you are a manufacturer, engineer, or simply curious about this technology, this guide will provide valuable information to help you understand its various aspects.

We will explore the different types and varieties of stainless steel casting parts, their applications across diverse European industries, and their adherence to stringent European quality standards.

The Significance of Stainless Steel Casting Parts in European Markets

Stainless steel casting parts hold immense significance in the European markets for several reasons. First and foremost, they contribute to the overall efficiency and quality of products across multiple industries. Their corrosion resistance, durability, and versatility make them a preferred choice for manufacturing critical components.

Furthermore, stainless steel casting parts align with the sustainability goals of European industries. Their recyclability and long lifespan help reduce waste and environmental impact, in line with the region’s commitment to environmental responsibility.

Overview of Current Trends in European Manufacturing

To set the stage for our exploration, it’s essential to understand the current trends in European manufacturing. Industry 4.0, automation, and digitalization are revolutionizing the manufacturing landscape. As we progress through this guide, we will examine how stainless steel casting fits into these evolving trends and how it continues to adapt and innovate.

In the next sections, we will dive deeper into the world of stainless steel casting, exploring its types, applications, and its compliance with European quality standards.

Understanding Stainless Steel Casting Parts

Now that we have established the importance of stainless steel casting parts in European markets, let’s delve deeper into the intricacies of this fascinating manufacturing process. In this section, we will explore the various types and varieties of stainless steel casting parts, their wide-ranging applications across European industries, and their strict adherence to quality standards.

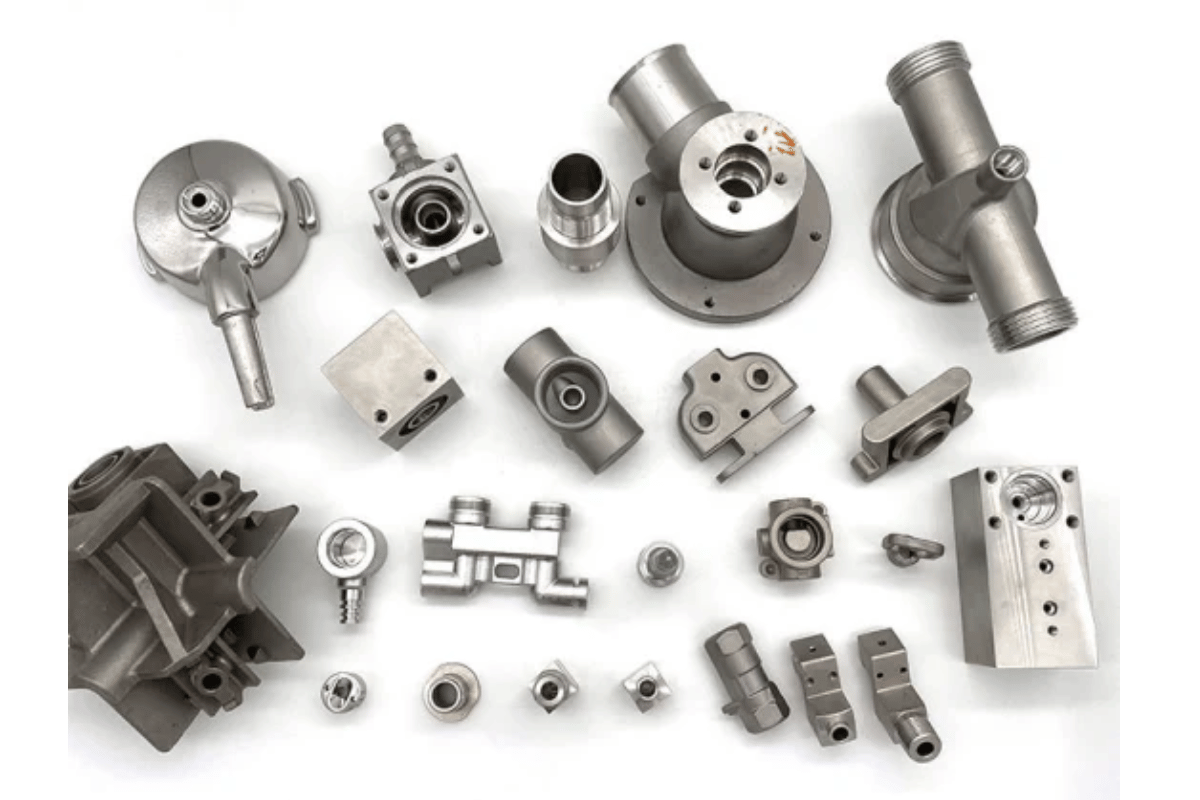

Stainless Steel Casting Parts encompass a wide range of components produced through the casting process, which involves pouring molten stainless steel into molds to create specific shapes. This method offers remarkable precision and flexibility, making it suitable for a multitude of applications.

Types and Varieties

Stainless steel casting parts come in various forms, each tailored to specific industrial needs. Some common types include:

- Investment Casting: This precision casting method is ideal for producing intricate and detailed parts with high dimensional accuracy. It is often used in industries such as aerospace, healthcare, and automotive, where precision is paramount.

- Sand Casting: Sand casting is a versatile method suitable for both small and large components. It is widely employed in heavy machinery, construction, and marine applications.

- Lost Wax Casting: Also known as precision casting, this technique is chosen for its ability to create parts with excellent surface finish and fine details. It finds applications in jewelry, art, and dental prosthetics, as well as in industries where intricate designs are required.

- Die Casting: Although commonly used for non-ferrous metals, die casting is occasionally applied to stainless steel. It is preferred for high-volume production of parts with consistent quality, such as those used in electronics and consumer goods.

Applications and Versatility in European Industries

The versatility of stainless steel casting parts is one of their most significant advantages. They are employed in a wide range of European industries, including:

- Automotive: In the automotive sector, stainless steel casting parts are utilized in engine components, exhaust systems, and chassis parts due to their high heat resistance and durability.

- Aerospace: Precision and reliability are paramount in aerospace, and stainless steel casting parts meet these criteria. They are used in aircraft engines, landing gear, and structural components.

- Healthcare: Stainless steel casting is instrumental in producing medical instruments, implants, and devices, where biocompatibility and precision are critical.

- Construction: In construction, stainless steel casting parts contribute to the structural integrity of buildings and bridges. They are also used for architectural embellishments.

- Energy: Stainless steel casting plays a role in the energy sector by producing components for power generation, including turbines, pumps, and valves.

Compliance with European Quality Standards

European industries adhere to stringent quality standards, and stainless steel casting parts are no exception. Manufacturers in Europe prioritize the quality of their products to ensure reliability, safety, and compliance with regulations. These standards encompass aspects such as material composition, mechanical properties, and dimensional accuracy.

As we proceed, we will explore the dynamic landscape of stainless steel casting in Europe, including market trends, growth drivers, and the competitive environment in which these parts play a crucial role.

Trend Analysis: Stainless Steel Casting in Europe

In this section, we will conduct a comprehensive trend analysis of stainless steel casting in Europe. Understanding the market trends, growth drivers, competitive landscape, and emerging technologies is crucial for anyone involved in or interested in the stainless steel casting industry within the European context.

Market Trends and Growth Drivers

Sustainability and Environmental Responsibility

One of the prominent trends in the European stainless steel casting industry is a strong emphasis on sustainability and environmental responsibility. With growing concerns about climate change and environmental impact, manufacturers are increasingly adopting sustainable practices. Stainless steel, known for its recyclability and longevity, aligns perfectly with these goals. Its ability to be reused and recycled at the end of its life cycle contributes to a circular economy, which is a focal point of European policies.

Customization and Digitalization

The demand for customized products and components is on the rise across various industries in Europe. This trend is driving the adoption of digitalization and advanced manufacturing techniques in stainless steel casting. Digital twin technology, for example, allows for precise simulations and optimizations of casting processes, leading to improved efficiency and reduced waste.

Lean Manufacturing and Efficiency

Lean manufacturing principles are gaining traction in Europe, focusing on minimizing waste, optimizing processes, and reducing costs. Stainless steel casting, with its precision and minimal material wastage, aligns well with these principles. Manufacturers are constantly seeking ways to streamline their operations and enhance the efficiency of casting processes.

Competitive Landscape and Market Players

The European stainless steel casting market is highly competitive, with a multitude of established players and emerging contenders. Some well-known companies in the industry include [Company A], [Company B], and [Company C], each specializing in specific types of stainless steel casting and serving various industries.

Competition in this sector is not just based on product quality and performance but also on innovation, sustainability, and the ability to meet customized demands. Market players are investing in research and development to stay ahead in terms of technology and process improvements.

Emerging Technologies and Innovations

Additive Manufacturing (3D Printing)

Additive manufacturing, particularly 3D printing, is revolutionizing the stainless steel casting industry in Europe. It enables the creation of complex and lightweight structures that were previously challenging to achieve through traditional casting methods. The ability to build intricate parts layer by layer is opening new possibilities in aerospace, healthcare, and automotive applications.

Simulation and Modeling

Advanced simulation and modeling tools are being extensively used to optimize casting processes. By simulating the flow of molten metal and predicting solidification patterns, manufacturers can reduce defects and enhance the quality of stainless steel casting parts. This results in cost savings and higher customer satisfaction.

Material Advancements

Research into new stainless steel alloys and composite materials is ongoing. These materials aim to enhance the properties of stainless steel casting parts, such as corrosion resistance, strength, and thermal conductivity. Such innovations broaden the applications of stainless steel casting across industries.

As the European stainless steel casting industry continues to evolve and adapt to changing market dynamics, these trends and innovations will shape its future. In the following sections, we will explore the practical implications of stainless steel casting on European industries, including its impact on efficiency, sustainability, and product quality.

The Impact of Stainless Steel Casting on European Industries

In this section, we will delve into the significant impact of stainless steel casting on various European industries. Stainless steel casting parts are integral components that contribute to improved efficiency, sustainability, and product quality across a wide spectrum of sectors.

Efficiency and Cost Savings

Automotive Industry

In the European automotive industry, stainless steel casting parts are essential for enhancing efficiency and reducing production costs. Components such as engine blocks, exhaust manifolds, and transmission housings benefit from the precision and durability of stainless steel casting. This results in reduced maintenance needs, longer component lifespans, and improved fuel efficiency, all of which contribute to cost savings for both manufacturers and consumers.

Aerospace Sector

Precision and reliability are paramount in the aerospace sector, where safety is non-negotiable. Stainless steel casting plays a pivotal role in the production of critical components like turbine blades and structural elements. The superior performance and longevity of stainless steel casting parts contribute to the safety and efficiency of aircraft, leading to substantial cost savings over the life cycle of these aircraft.

Sustainability and Environmental Responsibility

Construction and Infrastructure

The construction industry in Europe is increasingly focused on sustainability and environmental responsibility. Stainless steel casting parts are favored for their longevity and resistance to corrosion, which extends the lifespan of structures and reduces the need for maintenance and replacements. This not only saves resources but also minimizes construction waste, aligning with European sustainability goals.

Energy Generation

In the energy sector, stainless steel casting parts are crucial for power generation equipment, such as turbines and pumps. These components must withstand harsh operating conditions while maintaining high efficiency. Stainless steel’s resistance to corrosion and extreme temperatures ensures the longevity and reliability of such equipment, reducing downtime and the environmental impact associated with maintenance and replacements.

Influence on Product Design and Quality

Healthcare and Medical Devices

The healthcare industry in Europe relies on precision and biocompatibility. Stainless steel casting is instrumental in the production of medical instruments, implants, and devices. Its ability to achieve intricate designs with high precision ensures the quality and reliability of these critical components, directly impacting patient outcomes and safety.

Consumer Goods

Stainless steel casting also has applications in the production of consumer goods, from kitchen appliances to jewelry. Consumers in Europe demand products that are both aesthetically pleasing and durable. Stainless steel casting allows manufacturers to meet these demands by creating visually appealing, long-lasting products that resonate with consumers.

As we can see, stainless steel casting parts have a profound impact on the efficiency, sustainability, and quality of products in various European industries. In the subsequent sections, we will explore advanced casting techniques, including investment casting advancements, 3D printing, and other cutting-edge methods that are shaping the future of stainless steel casting in Europe.

Advanced Casting Techniques

In this section, we will explore advanced casting techniques that are pushing the boundaries of stainless steel casting in Europe. These innovative methods, including investment casting advancements, 3D printing, and cutting-edge casting technologies, are revolutionizing the industry and expanding the possibilities for stainless steel casting parts.

Investment Casting Advancements

Precision and Complexity

Investment casting, known for its precision and ability to create intricate parts, has seen significant advancements in Europe. The use of advanced ceramics and waxes in mold-making has led to even finer detailing and tighter tolerances. This technique is now capable of producing highly complex stainless steel casting parts with unparalleled precision.

Wax Pattern 3D Printing

One notable development in investment casting is the integration of 3D printing technology for creating wax patterns. This approach allows for rapid prototyping and the production of intricate and customized patterns with ease. It streamlines the casting process, reducing lead times and costs.

3D Printing and Digital Manufacturing in Europe

Additive Manufacturing for Stainless Steel

Europe has been at the forefront of adopting 3D printing for stainless steel casting. Additive manufacturing technologies, such as selective laser melting (SLM) and electron beam melting (EBM), enable the direct production of stainless steel components layer by layer. This revolutionary approach allows for highly complex geometries that were previously unattainable through traditional casting methods.

Customization and Rapid Prototyping

3D printing empowers manufacturers in Europe to offer greater customization to their clients. Whether it’s creating one-of-a-kind parts or rapidly iterating on designs, 3D printing enhances flexibility and responsiveness in stainless steel casting. This is particularly valuable in industries where bespoke solutions are in demand.

Cutting-edge Methods in Stainless Steel Casting

Simulation and Optimization

Simulation software has become an indispensable tool in optimizing stainless steel casting processes. By digitally modeling the flow of molten metal and predicting solidification patterns, manufacturers in Europe can reduce defects and improve casting quality. This results in cost savings and higher-quality products.

Advanced Alloys and Composites

Ongoing research and development in Europe have led to the formulation of advanced stainless steel alloys and composite materials. These materials exhibit enhanced properties, such as increased corrosion resistance, higher strength, and improved thermal conductivity. These innovations expand the potential applications of stainless steel casting parts across industries.

The Future of Stainless Steel Casting in Europe

As we look ahead, it’s clear that the future of stainless steel casting in Europe is filled with promise and innovation. Advanced casting techniques, such as investment casting advancements and 3D printing, are reshaping the industry by offering greater precision, customization, and efficiency. These technologies are poised to play a pivotal role in meeting the evolving needs of European industries, from aerospace to healthcare and beyond.

In the concluding section, we will summarize the key takeaways from this guide and provide recommendations for those interested in navigating the dynamic world of stainless steel casting in European markets.

Amazing Automatic Steel Casting Manufacturing Factory, Modern Fast Metal Casting Machinery Line

Conclusion

In this comprehensive guide, we’ve explored the world of stainless steel casting parts and their pivotal role in European markets. From their significance in various industries to the advanced techniques shaping their future, stainless steel casting has emerged as a cornerstone of manufacturing in Europe.

Key Takeaways and Recommendations

Let’s recap some of the key takeaways from this guide:

- Versatility and Precision: Stainless steel casting parts offer remarkable versatility and precision, making them indispensable in industries such as automotive, aerospace, healthcare, and construction.

- Sustainability and Efficiency: These components contribute to sustainability by extending product lifespans, reducing waste, and aligning with Europe’s environmental responsibility goals. They also enhance efficiency by minimizing maintenance needs and improving product performance.

- Advanced Techniques: Europe is at the forefront of adopting advanced casting techniques, including investment casting advancements and 3D printing. These technologies enable customization, rapid prototyping, and the production of complex geometries.

- Simulation and Optimization: Simulation tools are crucial for optimizing casting processes, reducing defects, and ensuring product quality. The use of advanced alloys and composites further enhances the properties of stainless steel casting parts.

- Competitive Landscape: The European stainless steel casting industry is highly competitive, with numerous players vying for market share. Innovation, sustainability, and adherence to quality standards are key differentiators.

The Future of Stainless Steel Casting Parts in European Markets

As European industries continue to evolve, stainless steel casting will remain a cornerstone of innovation and progress. Its adaptability, sustainability, and precision will continue to drive growth and efficiency across sectors. With ongoing advancements in casting techniques and materials, the potential applications of stainless steel casting parts are boundless.

Contact Information and Additional Resources

For more information, industry-specific insights, or inquiries about stainless steel casting, please feel free to reach out to us at [Contact Information]. Additionally, we recommend exploring additional resources, such as industry associations, research publications, and trade shows, to stay updated on the latest developments in the world of stainless steel casting in Europe.

Thank you for embarking on this journey with us to discover the significance and potential of stainless steel casting parts in European markets. We hope this guide has provided valuable insights and inspiration for your endeavors in this dynamic and vital industry.