Welcome to a journey into the world of precision manufacturing and technological innovation, where the mastery of CNC precision casting for CF8M stainless steel takes center stage in the year 2023. As we delve into the intricate realm of manufacturing excellence, we are poised to witness how CNC technology is reshaping the landscape of CF8M stainless steel casting, propelling it into new dimensions of accuracy and efficiency.

Recognizing the Importance of Precision Manufacturing and Technological Innovation

In a world driven by innovation, precision manufacturing stands as a cornerstone of progress. Every industry, from aerospace to medical devices, hinges on components that meet the highest standards of accuracy, durability, and reliability. It is within this context that CF8M stainless steel emerges as a stalwart material, renowned for its corrosion resistance and mechanical strength. However, the pursuit of perfection is a journey that often demands cutting-edge solutions, and that is precisely where CNC technology enters the scene.

Initial Insights into How CNC Is Transforming CF8M Stainless Steel Casting Processes

At the heart of this transformation lies the remarkable synergy between CF8M stainless steel and CNC precision casting. Computer Numerical Control (CNC) is more than a technology; it is an orchestra of digital precision, orchestrating every facet of the casting process with meticulous accuracy. From mold creation to post-processing, CNC’s touch ensures that CF8M stainless steel components are crafted with a level of precision that was once confined to the realm of dreams.

As we embark on this exploration, we will witness how the amalgamation of CF8M stainless steel and CNC technology results in a symphony of manufacturing mastery. Each stage of the process, from design to production, is infused with CNC’s precision, ushering CF8M stainless steel casting into a realm of unparalleled excellence. Join us as we uncover the intricacies of this transformative partnership and explore the innovative trends that are reshaping the manufacturing landscape in the year 2023 and beyond.

Exploring CF8M Stainless Steel Casting

Comprehensive Overview of CF8M Stainless Steel Casting and Its Significance in Various Industries

To understand the prowess of CNC precision casting for CF8M stainless steel, it’s essential to first delve into the material itself. CF8M stainless steel, a member of the austenitic family, is prized for its exceptional corrosion resistance, making it a preferred choice for applications where exposure to harsh environments and chemicals is commonplace. Industries spanning from chemical processing to marine engineering rely on CF8M stainless steel components to withstand the test of time.

Tracing the Historical Evolution of Casting Techniques, Highlighting the Shift Towards Advanced Methods

The journey of casting techniques has evolved through time, guided by the quest for higher quality and efficiency. Traditional casting methods, while effective, often introduced imperfections and limitations that fell short of modern demands. With the emergence of advanced methodologies, including precision casting, the realm of possibilities expanded dramatically. The introduction of CNC technology further elevated this evolution, bringing digital precision to a realm once governed by manual craftsmanship.

Identifying Challenges Inherent in Conventional Casting Approaches for CF8M Stainless Steel

While traditional casting techniques have served industries well, they are not without their challenges, particularly when it comes to materials like CF8M stainless steel. Achieving the necessary precision and consistency for complex geometries and intricate designs has proven to be a formidable task. Moreover, the potential for defects and irregularities in the final product posed a constant concern. It is within these challenges that the promise of CNC precision casting shines bright, offering a solution that redefines the standards of excellence in CF8M stainless steel manufacturing.

As we move forward, our exploration will delve deeper into the mechanics of CNC technology, unravelling the intricate dance of digital precision that shapes CF8M stainless steel casting. We will uncover how CNC’s orchestration transcends traditional limits, paving the way for a manufacturing landscape that is marked by accuracy, repeatability, and innovation.

Deconstructing CNC (Computer Numerical Control)

Detailed Explanation of CNC Technology, Encompassing Its Fundamental Principles and Operational Mechanics

To fully appreciate the transformation that CNC precision casting brings to CF8M stainless steel, it’s imperative to comprehend the inner workings of Computer Numerical Control (CNC). At its core, CNC is a technological marvel that marries computation with craftsmanship, automating machining processes to achieve unprecedented levels of precision.

CNC Systems Automate Machining Processes to Achieve Accuracy and Efficiency

Imagine a symphony conducted by lines of code. CNC systems, driven by these codes, meticulously control machine tools with a precision that human hands can seldom match. This automation extends from intricate cuts to complex movements, ensuring that each movement is executed with mathematical exactitude. In the context of CF8M stainless steel casting, CNC transforms the casting process into a symphony of precision, orchestrating every step with the aim of perfection.

Highlighting the Benefits of CNC Adoption, Including Precision, Repeatability, and Intricate Design Capabilities

The adoption of CNC technology ushers in a new era of manufacturing excellence, particularly when dealing with materials as critical as CF8M stainless steel. The foremost advantage is precision. CNC’s ability to replicate digital designs with microscopic accuracy ensures that each CF8M stainless steel component meets the strictest tolerances, guaranteeing uniformity and reliability.

Repeatability is another hallmark of CNC technology. The process’s digital nature ensures that every cast, every mold, and every component can be reproduced identically, eliminating the variability inherent in traditional methods. This is of paramount importance when consistency is a non-negotiable requirement.

Perhaps most astonishing is CNC’s intricate design capabilities. Complex geometries that were once deemed unachievable are now within reach. Whether it’s internal cavities, intricate patterns, or delicate contours, CNC machines sculpt CF8M stainless steel with a precision that is not only awe-inspiring but also essential for applications demanding intricate and tailored designs.

In the subsequent section, we will delve into how CNC technology is seamlessly integrated into CF8M stainless steel casting, unraveling the intricate dance of precision that transforms raw materials into flawless components. This exploration will lay bare the ways in which CNC technology is redefining the norms of manufacturing, leading CF8M stainless steel casting into an era of unparalleled quality and innovation.

Mastering CF8M Stainless Steel Casting through CNC Precision

Exploration of How CNC Technology Is Integrated into CF8M Stainless Steel Casting to Achieve Mastery

The integration of CNC technology into CF8M stainless steel casting marks a pivotal turning point in the manufacturing landscape. This convergence of digital precision and metallurgical excellence redefines the standards of quality and efficiency. Let’s embark on a journey through the stages where CNC’s touch shapes CF8M stainless steel into components of unparalleled mastery.

Step-by-Step Breakdown of CNC’s Role in Mold Creation, Casting, and Post-Processing

The journey commences with mold creation, where CNC’s precision is harnessed to carve out molds with exacting dimensions. Every contour, every intricacy is translated from the digital realm to the physical, ensuring that each mold faithfully represents the intended design. This is where the foundation of excellence is laid, setting the stage for flawless casting.

As the molten CF8M stainless steel flows into the mold during the casting phase, CNC’s orchestration continues. The intricacies of the mold design are mirrored in the cast component, with CNC guiding the cooling process to prevent defects and ensure uniformity. Every pore, every grain is aligned with the intended design, fostering mechanical properties that meet the highest standards.

Post-casting, CNC’s role shines in the realm of post-processing. Every edge, every surface is refined to perfection, achieving a level of smoothness that is not only aesthetic but also functional. Threads are precisely cut, surfaces are meticulously polished, and dimensions are scrutinized, all under the watchful eye of CNC precision.

Emphasizing the Advantages of CNC Integration, Such as Enhanced Quality, Reduced Errors, and Optimized Production

The advantages of CNC precision casting for CF8M stainless steel are manifold. Enhanced quality stems from CNC’s unwavering commitment to precision, resulting in components that meet or exceed specifications with remarkable consistency. The potential for human errors that plague manual processes is nearly eradicated, ushering in a new era of reliability.

Reduced errors further contribute to this reliability. The digital nature of CNC ensures that deviations are minimized, if not eliminated entirely. The result is a production line that is more predictable, yielding components that are indistinguishable from one another in terms of quality and performance.

The integration of CNC technology optimizes production as well. With repeatability at its core, CNC systems enable faster turnaround times and increased output. This is of particular importance when addressing the demands of industries where timing is paramount.

As we journey forward, our exploration will pivot towards the innovative trends that are shaping the landscape of manufacturing in 2023. From the integration of AI to real-time monitoring, these trends further amplify the capabilities of CNC precision casting, driving CF8M stainless steel casting towards new frontiers of excellence.

Innovative Trends in 2023 Manufacturing

Exploring the Latest Trends and Innovations in CNC Technology Relevant to Precision Casting

The landscape of manufacturing is a canvas constantly painted with innovation. In the year 2023, as we delve into the realm of CF8M stainless steel casting, the integration of CNC technology is further enhanced by a spectrum of cutting-edge trends. These trends, poised at the intersection of technology and manufacturing, propel CF8M stainless steel casting into an era of unparalleled efficiency and excellence.

Integration of AI, Machine Learning, and Real-Time Monitoring for Process Optimization

Artificial Intelligence (AI) and machine learning are no longer confined to science fiction; they are the catalysts driving manufacturing forward. The synergy between AI, machine learning, and CNC technology ushers in a new era of process optimization. The ability to predict and adapt to variations in the casting process is a game-changer. Machine learning algorithms analyze data from each casting iteration, refining parameters for subsequent casts to achieve optimal results. This adaptive intelligence enhances efficiency, reduces waste, and minimizes the margin for error.

Furthermore, real-time monitoring ensures that each stage of the casting process is scrutinized with unparalleled precision. Sensors collect data on temperature, pressure, and other critical parameters, feeding the information into AI algorithms that can detect anomalies and make necessary adjustments on the fly. The result is a level of quality control that was previously unattainable.

Presenting Real-World Examples of Successful CNC Integration in the Global Manufacturing Landscape

The success stories of CNC integration extend across the global manufacturing landscape. From aerospace to automotive, industries are leveraging the power of CNC precision casting for materials like CF8M stainless steel. In the aerospace sector, where safety is paramount, CNC ensures that every component meets stringent standards with absolute precision. In the automotive realm, where efficiency is key, CNC streamlines production while maintaining uncompromised quality.

These real-world examples showcase the versatility of CNC technology and its profound impact on industries that demand excellence. As we move forward, our exploration will take a closer look at the European manufacturing perspective, delving into how the integration of CNC technology has reshaped CF8M stainless steel casting within the European context.

European Manufacturing Perspective: CNC and CF8M Stainless Steel Casting

Providing Insights into the European Viewpoint on Advanced Manufacturing Techniques, with a Focus on CNC

The European manufacturing landscape stands as a testament to precision, quality, and innovation. Within this context, the integration of CNC technology into CF8M stainless steel casting has garnered significant attention. European foundries, renowned for their commitment to excellence, have embraced CNC precision casting to redefine the norms of manufacturing.

Showcasing Notable European Foundries Leading the Way in CF8M Stainless Steel Casting Using CNC

European foundries have always been at the forefront of adopting advanced manufacturing techniques. The integration of CNC technology into CF8M stainless steel casting is a natural progression of this ethos. Prominent foundries have harnessed CNC’s capabilities to elevate CF8M stainless steel components to new heights of precision and efficiency. Whether for marine applications or medical devices, these foundries have demonstrated that CNC precision casting is not just a technological choice but a strategic advantage.

Ensuring Compliance with European Quality Standards and Regulatory Requirements

The European manufacturing landscape is synonymous with stringent quality standards and regulatory compliance. The integration of CNC precision casting into CF8M stainless steel manufacturing aligns seamlessly with these values. Every component, every process adheres to a level of excellence that is upheld by European standards. This adherence ensures that each CF8M stainless steel component is not only a masterpiece of craftsmanship but also a testament to compliance with the highest manufacturing norms.

As we conclude our exploration, it’s important to revisit the key takeaways that have woven through this journey. The partnership between CNC technology and CF8M stainless steel casting is a marriage of digital precision and metallurgical excellence. It transforms the realm of manufacturing into an arena of mastery, where quality and innovation converge. As we peer into the horizon of manufacturing’s future, the legacy of CNC-enabled CF8M stainless steel casting stands as a beacon, guiding industries towards a future defined by precision, efficiency, and technological marvels.

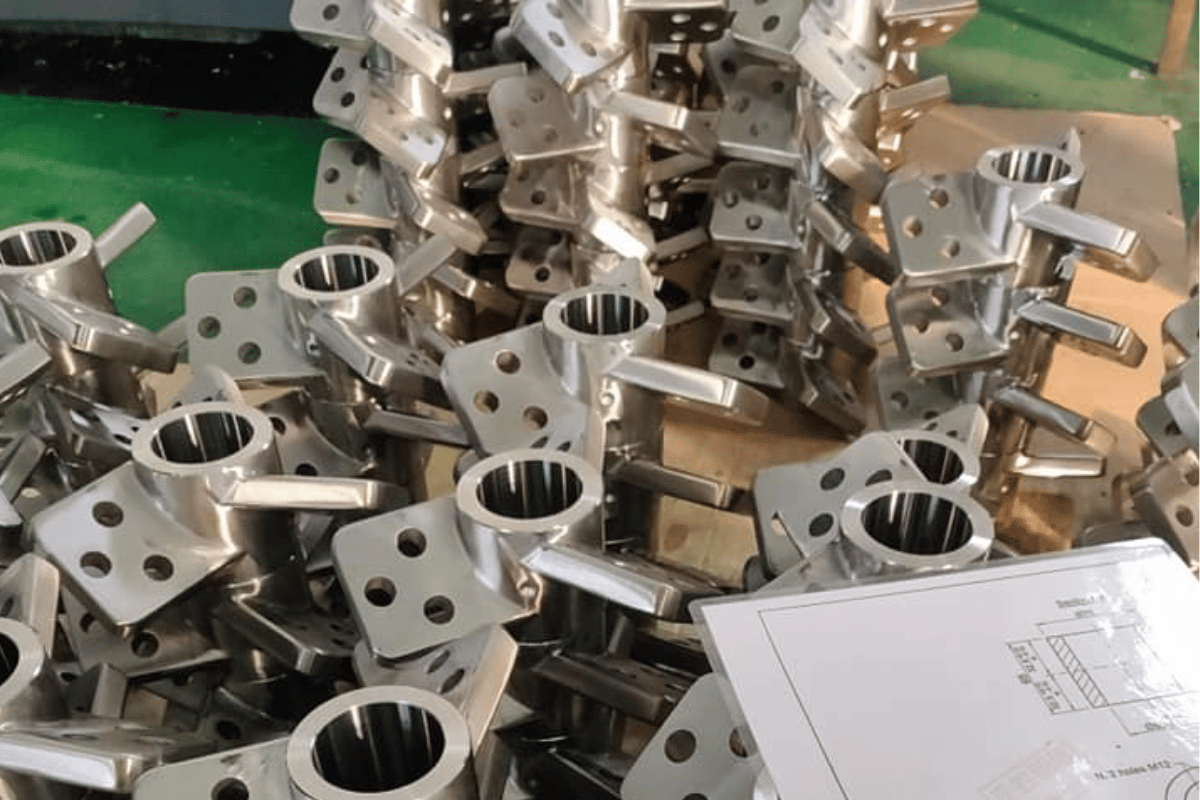

AISI 347 stainless steel parts supplier,cf3m/cf8m/SUS304/316 stainless steel castings,1.4408 foundry

Conclusion

Summarizing the Key Takeaways from the Outlined Content

In the realm of precision manufacturing, where excellence is not a goal but an expectation, the integration of CNC technology into CF8M stainless steel casting marks a turning point. This journey through the mastery of CNC precision casting has unveiled a landscape where innovation, precision, and efficiency converge to reshape the norms of manufacturing.

Highlighting the Pivotal Role of CNC in Achieving Mastery in CF8M Stainless Steel Casting

CNC technology’s role in the transformation of CF8M stainless steel casting cannot be overstated. It is the symphony conductor of precision, orchestrating each step with digital finesse. From mold creation to post-processing, CNC’s touch ensures that every contour, every surface is a testament to excellence. The advantages are manifold – enhanced quality, reduced errors, and optimized production. Each CF8M stainless steel component stands as a testament to CNC’s prowess.

Looking Ahead to Continuous Advancements and Growth in the Domain of CNC-Enabled Manufacturing Innovations

The journey through the mastery of CNC precision casting for CF8M stainless steel is not a culmination but a stepping stone. As the manufacturing landscape continues to evolve, the integration of AI, machine learning, and real-time monitoring will amplify CNC’s capabilities. The future promises a manufacturing realm where precision is not a rarity but a standard, where excellence is not an aspiration but an assurance.

In closing, the legacy of CNC-enabled CF8M stainless steel casting is a legacy of precision, innovation, and transformation. The fusion of digital precision and metallurgical mastery sets the stage for a manufacturing future where the boundaries of excellence are constantly redefined. As industries venture forth, they do so with the knowledge that CNC technology is not just a tool but a partner, guiding them towards a horizon where precision knows no limits.