Welcome to this comprehensive exploration of Investment Casting Systems Ltd (ICS Ltd) and its pivotal role in shaping the future of European manufacturing. In this introductory section, we will provide an overview of ICS Ltd, delve into the influence it exerts on the European manufacturing landscape, and underline the significance of European manufacturing in the year 2023.

Overview of Investment Casting Systems Ltd (ICS Ltd)

Investment Casting Systems Ltd (ICS Ltd) stands at the forefront of precision casting technology and manufacturing solutions. With a rich history and a commitment to innovation, ICS Ltd has become a cornerstone of European manufacturing excellence. The company’s dedication to quality, precision, and efficiency has earned it a prominent position in the European industrial landscape.

The Role of ICS Ltd in Shaping the Future of European Manufacturing

In an era of rapid technological advancements and evolving global markets, the role of ICS Ltd in shaping the future of European manufacturing cannot be overstated. The company’s cutting-edge technologies and unwavering commitment to excellence have not only propelled its own success but have also played a vital role in advancing European manufacturing as a whole.

ICS Ltd’s influence extends beyond the confines of its facilities. It is a driving force behind the innovation and competitiveness of European industries, ensuring that they remain at the forefront of global manufacturing.

Significance of European Manufacturing in 2023

As we step into the year 2023, European manufacturing holds a pivotal position in the global economy. European industries are renowned for their commitment to quality, precision, and sustainability. This reputation has made them leaders in various sectors, including aerospace, automotive, medical devices, and more.

The significance of European manufacturing lies not only in its economic impact but also in its contribution to technological advancement and environmental responsibility. In a world that values sustainable practices and high-quality products, European manufacturing continues to be a beacon of excellence.

As we progress through this guide, we will delve deeper into the technologies and contributions of ICS Ltd in European manufacturing, exploring how it continues to shape and elevate the industry to new heights.

Investment Casting Technology

In this section, we embark on a journey into the realm of investment casting technology, a cornerstone of modern manufacturing, and explore its historical context within Europe. We will also delve into the key technologies employed by Investment Casting Systems Ltd (ICS Ltd), shedding light on the significance of these innovations.

Explanation of Investment Casting and Its Importance in Manufacturing

Investment casting, often referred to as “lost wax casting,” is a sophisticated manufacturing process renowned for its precision and versatility. At its core, investment casting involves the creation of intricate molds from wax patterns. These molds are then used to produce high-precision metal components with complex geometries.

The importance of investment casting in manufacturing cannot be overstated. This technique enables the production of components with minimal material waste, exceptional surface finish, and precise dimensional accuracy. It finds applications across various industries, including aerospace, automotive, medical devices, and more.

Historical Context of Investment Casting in Europe

Investment casting has deep historical roots in Europe, dating back thousands of years. The origins of this technique can be traced to ancient civilizations where it was used to create intricate jewelry, religious artifacts, and even sculptures. Throughout European history, investment casting has played a crucial role in the production of ornate metalwork and artistic pieces.

In more recent times, investment casting has evolved from traditional craftsmanship into a sophisticated manufacturing method that combines craftsmanship with advanced technology. European artisans and engineers have continually refined and expanded the applications of investment casting, contributing to its prominence in contemporary manufacturing.

Key Technologies Employed by ICS Ltd

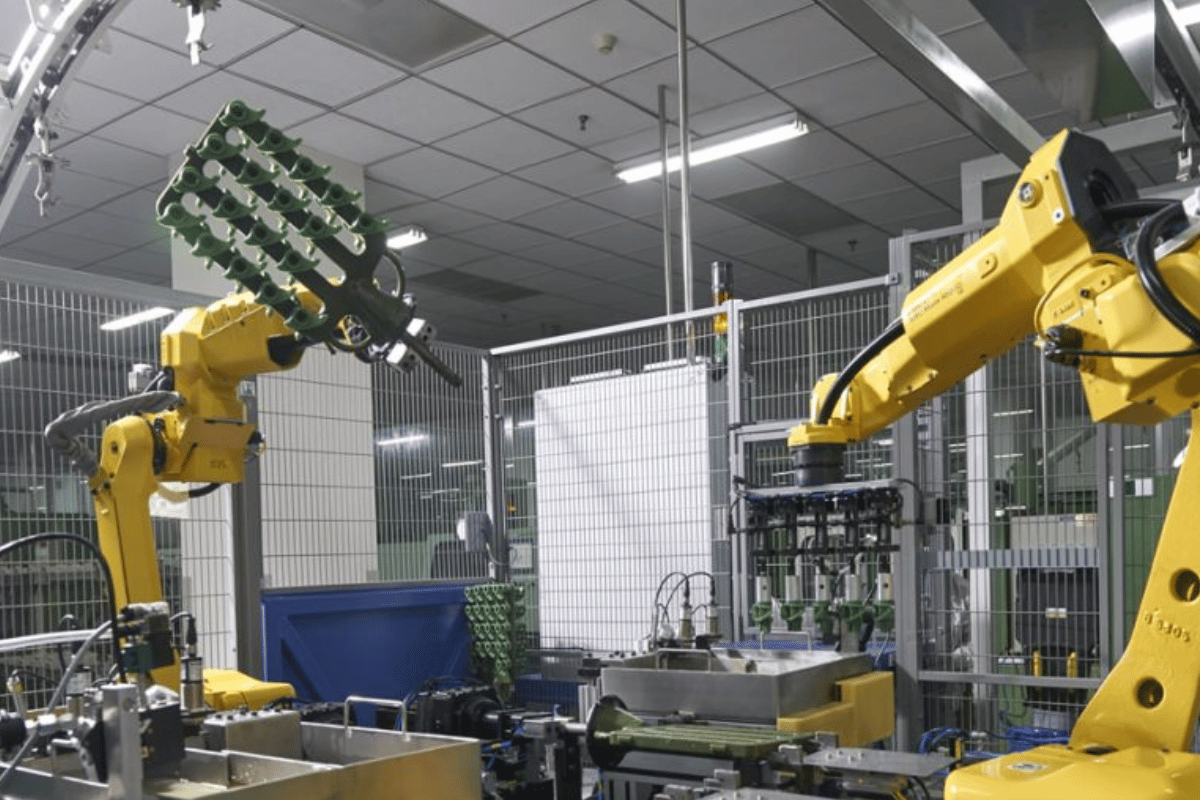

Investment Casting Systems Ltd (ICS Ltd) has been a pioneer in advancing investment casting technology. The company employs a range of cutting-edge technologies to optimize the casting process and ensure the highest quality of components. Some key technologies and techniques utilized by ICS Ltd include:

- Computer-Aided Design (CAD): ICS Ltd harnesses CAD software to design intricate wax patterns with precision. This digital approach allows for the rapid prototyping of components, reducing lead times and enhancing design accuracy.

- 3D Printing: The integration of 3D printing technology enables ICS Ltd to create complex and highly detailed wax patterns, pushing the boundaries of what is achievable in investment casting.

- Advanced Materials: ICS Ltd continuously explores and utilizes advanced materials, including specialized alloys and ceramics, to meet the stringent requirements of modern industries.

- Quality Control Systems: The implementation of advanced quality control systems and non-destructive testing methods ensures that every component produced by ICS Ltd meets the highest standards of precision and reliability.

In the following sections, we will delve deeper into the contributions of ICS Ltd to European manufacturing, highlighting the company’s operations and successful collaborations with industries across the continent.

ICS Ltd’s Contribution to European Manufacturing

In this section, we will take a closer look at the operations and impact of Investment Casting Systems Ltd (ICS Ltd) within the realm of European manufacturing. We will explore the company’s extensive contributions and its collaborative efforts with various European industries, exemplified through case studies showcasing successful partnerships.

Overview of ICS Ltd’s Operations and Impact

ICS Ltd has established itself as a leading force in European manufacturing, renowned for its commitment to precision, quality, and innovation. The company’s operations encompass a wide range of activities, all of which are geared towards advancing the art of investment casting and enhancing the competitiveness of European industries.

At the core of ICS Ltd’s operations lies a dedication to research and development, where teams of experts continuously explore new materials, technologies, and techniques to push the boundaries of what is achievable in investment casting.

Collaborations with European Industries

One of the key strengths of ICS Ltd is its collaborative approach to industry partnerships. The company actively collaborates with various European industries, sharing its expertise and resources to address specific manufacturing challenges and foster innovation.

These collaborations span a multitude of sectors:

- Aerospace: ICS Ltd has been a key partner in the aerospace industry, providing precision-cast components that meet the demanding requirements of this sector. These components are crucial for ensuring the safety and efficiency of aircraft and spacecraft.

- Automotive: The automotive industry relies on ICS Ltd’s expertise to produce components that are not only precise but also durable and lightweight. Investment casting plays a pivotal role in enhancing the performance of modern vehicles.

- Medical Devices: ICS Ltd’s contributions extend to the medical field, where the precision of investment casting is indispensable for manufacturing intricate and life-saving medical devices.

Case Studies Showcasing Successful Partnerships

Let’s delve into a couple of case studies that highlight ICS Ltd’s successful partnerships with European industries:

Case Study 1: Aerospace Innovation

In collaboration with a leading European aerospace manufacturer, ICS Ltd contributed to the development of a groundbreaking turbine blade design for jet engines. The investment-cast turbine blades, crafted with exceptional precision, enhanced engine efficiency, reduced fuel consumption, and contributed to a significant reduction in emissions. This partnership exemplifies how ICS Ltd plays a vital role in advancing technology and sustainability within the aerospace sector.

Case Study 2: Automotive Advancements

ICS Ltd partnered with a prominent European automaker to produce intricate transmission components using investment casting. The resulting components were not only lighter and more durable but also exhibited reduced friction, contributing to improved fuel efficiency and overall vehicle performance. This collaboration underscores ICS Ltd’s impact on enhancing automotive technology and efficiency.

These case studies exemplify how ICS Ltd’s commitment to innovation and precision casting continues to drive advancements in European manufacturing across diverse industries. As we progress through this guide, we will explore the critical aspect of quality assurance and adherence to European manufacturing standards, further solidifying ICS Ltd’s role in shaping the future of European manufacturing.

Quality Assurance and Standards

In this section, we delve into the critical aspect of quality assurance and the rigorous standards upheld by Investment Casting Systems Ltd (ICS Ltd) in its manufacturing processes. We will explore how ICS Ltd ensures high-quality manufacturing and its unwavering adherence to European manufacturing standards. Additionally, we will shed light on the quality control measures implemented by the company to maintain excellence.

Ensuring High-Quality Manufacturing

Quality is the cornerstone of ICS Ltd’s operations, and it permeates every stage of the manufacturing process. The company’s commitment to delivering high-quality components is paramount, as these components often play vital roles in safety-critical applications such as aerospace, automotive, and healthcare.

To ensure high-quality manufacturing, ICS Ltd employs a comprehensive approach that encompasses the following key elements:

- Precision Casting: ICS Ltd utilizes state-of-the-art casting techniques to achieve precision that meets or exceeds industry standards. The investment casting process itself is inherently capable of producing components with exceptional dimensional accuracy and surface finish.

- Advanced Materials: The selection of materials is a critical factor in quality assurance. ICS Ltd works closely with its clients to choose the most suitable materials for specific applications, taking into account factors such as strength, durability, and corrosion resistance.

- Quality Control Systems: ICS Ltd has established stringent quality control systems that govern every phase of production. These systems include comprehensive inspections, testing, and verification procedures to ensure that each component meets the specified standards.

Adherence to European Manufacturing Standards

ICS Ltd takes great pride in adhering to European manufacturing standards, which are known for their rigor and commitment to excellence. The company’s compliance with these standards is not only a matter of regulatory requirement but also a testament to its dedication to delivering the highest quality products to its customers.

European manufacturing standards cover various aspects of production, including material specifications, testing methods, and safety protocols. By aligning its practices with these standards, ICS Ltd provides its clients with components that are not only of the highest quality but also compliant with regional and international regulations.

Quality Control Measures Employed by ICS Ltd

Investment Casting Systems Ltd has implemented a series of quality control measures designed to monitor and maintain the highest standards throughout the manufacturing process:

- Non-Destructive Testing (NDT): NDT methods, such as X-ray and ultrasonic testing, are routinely employed to detect any internal defects or irregularities in cast components. This ensures that only flawless components reach the final stage.

- Dimensional Inspection: ICS Ltd conducts rigorous dimensional inspections to verify that each component conforms to the precise specifications outlined by the client. Any deviations are promptly addressed to maintain accuracy.

- Material Testing: Comprehensive material testing ensures that the chosen materials meet the required mechanical properties and chemical composition, guaranteeing the integrity of the final product.

- Traceability: A robust traceability system is in place to track each component from the initial design phase through to manufacturing and delivery. This traceability ensures accountability and facilitates any necessary post-production evaluations.

As we conclude this section, we recognize that ICS Ltd’s unwavering commitment to quality assurance and adherence to European manufacturing standards underpin its reputation as a trusted partner in delivering high-quality, precision-cast components. In the final section, we will recap the key takeaways from this guide and acknowledge the significant role that ICS Ltd plays in European manufacturing.

Precision castings – Lost-wax castings

Conclusion

As we reach the culmination of this comprehensive guide, it is fitting to recap the key takeaways and acknowledge the profound role that Investment Casting Systems Ltd (ICS Ltd) plays in the landscape of European manufacturing. We will also offer an encouraging note for the future, emphasizing the importance of continued innovation and growth.

Recap of Key Takeaways

- Precision and Innovation: ICS Ltd stands as a beacon of precision and innovation in the realm of investment casting technology. Its unwavering commitment to delivering high-quality, precision-cast components is a testament to its dedication to excellence.

- Collaborative Partnerships: The company’s collaborative approach with European industries has led to successful partnerships that drive advancements across sectors, including aerospace, automotive, and medical devices.

- Adherence to Standards: ICS Ltd’s adherence to European manufacturing standards ensures that its components not only meet regulatory requirements but also maintain the highest quality and safety standards.

- Quality Control: Rigorous quality control measures, including non-destructive testing and dimensional inspections, are employed to guarantee that each component meets the specified standards.

- Innovation and Sustainability: The company’s continuous investment in research and development, exploration of advanced materials, and embrace of sustainable practices contribute to the evolution of investment casting technology.

Acknowledgment of ICS Ltd’s Role in European Manufacturing

ICS Ltd has played a pivotal role in shaping the future of European manufacturing. Its unwavering commitment to precision, quality, and innovation has not only propelled its own success but has also contributed significantly to the competitiveness and technological advancement of European industries.

The company’s dedication to collaborative partnerships, compliance with European manufacturing standards, and stringent quality control measures have made it a trusted partner for industries across the continent. ICS Ltd’s contributions extend far beyond its facilities, impacting the efficiency, sustainability, and safety of various sectors.

Encouragement for Continued Innovation and Growth

As we look to the future, it is essential to recognize that innovation and growth are the lifeblood of the manufacturing industry. ICS Ltd’s role in advancing investment casting technology serves as an inspiration for continued exploration and improvement.

We encourage not only ICS Ltd but all stakeholders in European manufacturing to embrace innovation, sustainability, and collaboration. Together, we can continue to push the boundaries of what is possible, drive progress, and maintain Europe’s position as a global leader in manufacturing excellence.

In conclusion, Investment Casting Systems Ltd (ICS Ltd) stands as a symbol of precision, quality, and innovation in European manufacturing. Its journey is a testament to the enduring spirit of advancement and the unwavering commitment to excellence that defines the European manufacturing landscape.