Welcome to this comprehensive guide on investment casting automotive parts and their vital role in the European manufacturing landscape. In this section, we will outline the purpose and scope of this guide, emphasize the significance of investment casting automotive parts for European manufacturers, and provide an overview of the European automotive manufacturing landscape.

Investment casting has become synonymous with precision and complexity in the production of critical automotive components. As European manufacturers strive for excellence in quality and performance, understanding the nuances of investment casting in this context is paramount.

Purpose and Scope of the Guide

The primary aim of this guide is to provide a comprehensive resource for those seeking insights into investment casting within the European automotive sector. Whether you are a manufacturer, engineer, or simply interested in the intricacies of automotive production, this guide will offer valuable information to help you navigate the world of investment casting automotive parts.

We will delve into the key components and applications of investment casting in automotive production, explore the benefits it offers to European manufacturers, and examine how it aligns with stringent European quality standards.

The Significance of Investment Casting Automotive Parts for European Manufacturers

Investment casting is not merely a manufacturing process; it is a cornerstone of quality, precision, and innovation in the European automotive industry. European manufacturers rely on investment casting to create components that meet the highest standards of performance and safety.

Investment casting automotive parts play a pivotal role in ensuring the efficiency, reliability, and competitiveness of European automotive manufacturers. As we progress through this guide, we will delve deeper into the world of investment casting, shedding light on its key components, applications, and its integral role in European automotive manufacturing.

Understanding Investment Casting in Automotive Production

In this section, we will delve into the intricate world of investment casting as it pertains to automotive production in Europe. We will explore the key components and applications of investment casting, highlight the benefits it brings to European automotive manufacturing, and emphasize its alignment with stringent European quality standards.

Investment casting automotive parts represent the epitome of precision and craftsmanship in the automotive industry, making them indispensable for European manufacturers aiming for excellence.

Key Components and Applications

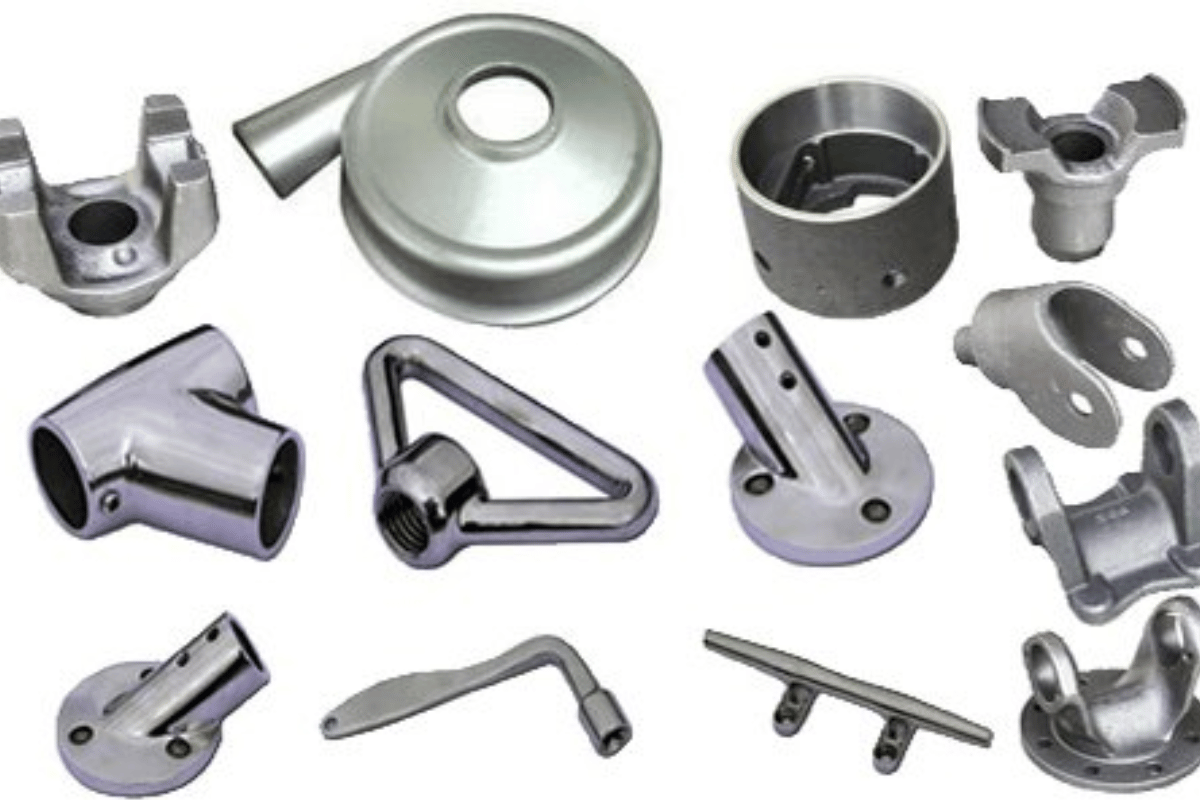

Investment casting finds extensive application in the automotive sector, producing critical components that contribute to the performance and reliability of vehicles. Some key components and their applications include:

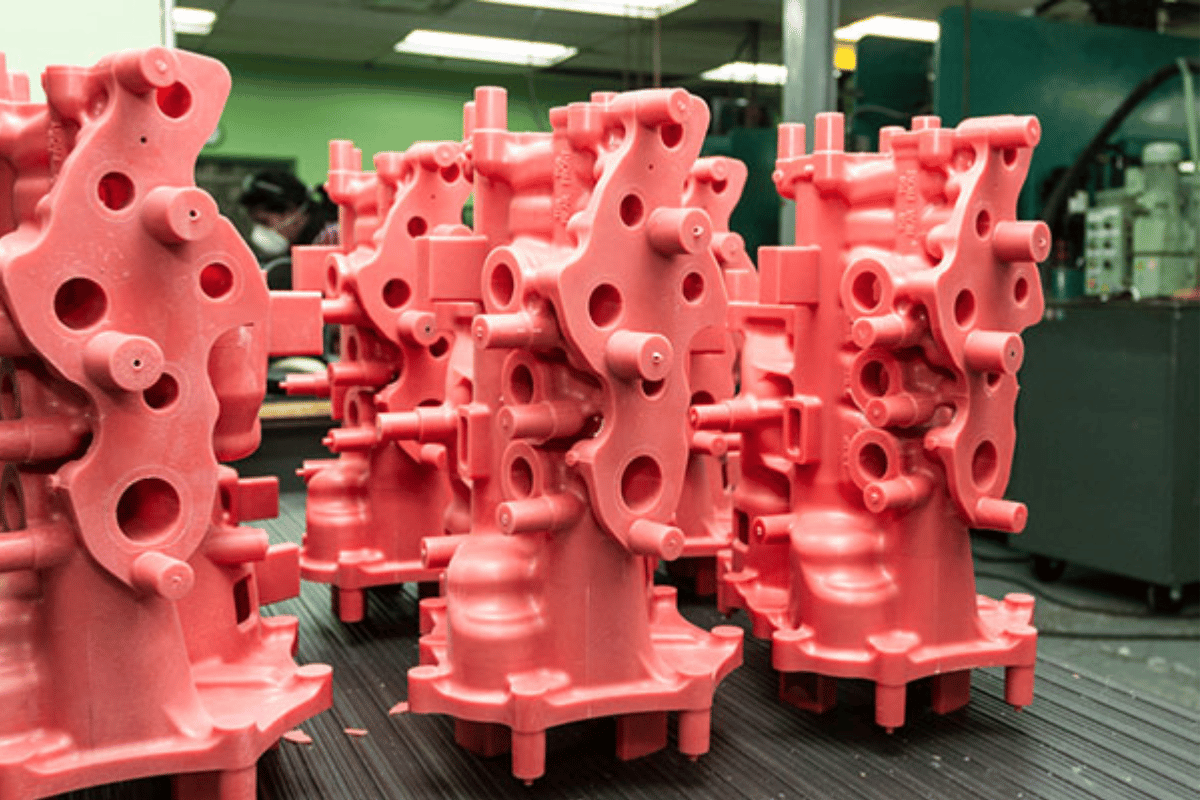

- Engine Components: Investment casting is used to create intricate components such as turbine blades, exhaust manifolds, and cylinder heads. These components must withstand high temperatures and pressures while maintaining optimal efficiency.

- Transmission Parts: Precision is paramount in transmission components. Investment casting enables the creation of gears, shafts, and housings with exceptional dimensional accuracy, ensuring smooth and reliable operation.

- Suspension and Steering Components: Investment casting is employed to manufacture components like suspension arms, steering knuckles, and control arms. These parts must balance strength, weight, and durability, and investment casting delivers on these requirements.

- Aesthetic Elements: Beyond functionality, investment casting is used to craft aesthetically pleasing elements in vehicle design, such as emblems, grilles, and trim pieces. These components enhance the overall look and feel of the vehicle.

Benefits in European Automotive Manufacturing

Precision and Complexity

Investment casting is renowned for its ability to create complex geometries and intricate details with remarkable precision. In the European automotive industry, where performance and safety are paramount, this precision is indispensable. Manufacturers can achieve tolerances and intricacies that would be challenging or impossible with other casting methods.

Weight Reduction for Improved Efficiency

Efficiency and environmental responsibility are top priorities in European automotive manufacturing. Investment casting allows for the creation of lightweight yet robust components. Reduced weight in critical parts, such as engine components and chassis elements, contributes to improved fuel efficiency and overall vehicle performance.

Enhanced Aesthetics and Performance

Investment casting is not just about functionality; it’s also about aesthetics. European manufacturers utilize investment casting to create visually appealing components that enhance the overall design and performance of vehicles. These components often serve as distinctive features that set vehicles apart in the market.

As we continue through this guide, we will delve deeper into the world of investment casting automotive parts, exploring the quality control procedures and certifications that ensure the reliability of these components in European vehicles.

Quality Assurance in Investment Casting

Ensuring the quality and reliability of investment casting automotive parts is paramount in European automotive manufacturing. In this section, we will delve into the rigorous quality control procedures and certifications that underpin the excellence of investment casting in this context. We will also explore the continuous improvement initiatives that drive the industry towards ever-higher standards.

Quality Control Procedures and Certifications

Metallurgical Analysis

Before a component leaves the casting facility, it undergoes meticulous metallurgical analysis. This involves examining the material’s composition, microstructure, and mechanical properties to ensure it meets precise specifications. European manufacturers adhere to international standards for these analyses, guaranteeing the consistency and integrity of their products.

Non-Destructive Testing (NDT)

Non-destructive testing methods, including radiographic, ultrasonic, and magnetic particle testing, are employed to detect any hidden flaws or defects in investment casting automotive parts. These tests provide an added layer of assurance regarding the structural soundness of critical components.

Dimensional Accuracy

Precision is a hallmark of investment casting, and European manufacturers use advanced metrology equipment to verify the dimensional accuracy of components. Automated measurement systems ensure that components conform to exacting tolerances.

Certifications

European manufacturers of investment casting automotive parts often hold certifications such as ISO 9001 and IATF 16949, which are internationally recognized quality management standards. These certifications demonstrate a commitment to excellence and compliance with rigorous quality control processes.

Continuous Improvement Initiatives

Lean Manufacturing

Many European manufacturers embrace lean manufacturing principles, seeking to eliminate waste, streamline processes, and enhance the efficiency of their investment casting operations. This results in cost savings and improved product quality.

Six Sigma and Process Optimization

Six Sigma methodologies are applied to minimize process variations and defects in investment casting. Statistical analysis and process optimization techniques are used to identify and rectify potential issues before they impact product quality.

Collaborative Problem-Solving

European manufacturers actively collaborate with their customers and suppliers to address challenges and drive continuous improvement. This collaborative approach fosters innovation and ensures that investment casting automotive parts consistently meet or exceed expectations.

Meeting European Automotive Industry Standards

The European automotive industry maintains strict standards for quality, safety, and environmental responsibility. Investment casting automotive parts must align with these standards to earn their place in European vehicles. Manufacturers in Europe understand the importance of meeting these stringent requirements and invest in the necessary infrastructure, technology, and expertise to ensure compliance.

In the subsequent section, we will explore the advantages of investment casting in the automotive sector, including its ability to achieve precision and complexity in design, reduce weight for improved efficiency, and enhance both aesthetics and performance in European vehicles.

Advantages of Investment Casting in the Automotive Sector

Investment casting has become an indispensable technique in the European automotive sector, offering a multitude of advantages that contribute to the excellence of automotive manufacturing. In this section, we will explore the key advantages of using investment casting for automotive parts, including precision and complexity in design, weight reduction for improved efficiency, and enhanced aesthetics and performance.

Precision and Complexity in Design

Intricate Geometries

Investment casting is renowned for its ability to create intricate and highly detailed components. In the automotive sector, this translates to the production of parts with complex geometries, such as turbine blades, which are crucial for optimizing engine performance. The precision achieved through investment casting ensures that these components meet exacting specifications, leading to improved vehicle efficiency and reliability.

Reduced Machining

Investment casting often requires minimal post-casting machining, as the process yields near-net shape parts. This reduces the need for extensive and costly machining operations, saving time and resources in the manufacturing process. European automotive manufacturers benefit from these efficiency gains, allowing them to allocate resources to other critical areas of production.

Weight Reduction for Improved Efficiency

Lightweight Components

Efficiency and sustainability are top priorities in the European automotive industry. Investment casting enables the creation of lightweight yet structurally sound components. These components, when integrated into vehicles, contribute to reduced overall vehicle weight. Lighter vehicles consume less fuel, resulting in improved fuel efficiency and reduced emissions, aligning with Europe’s stringent environmental regulations.

Enhanced Fuel Economy

Reducing vehicle weight directly impacts fuel economy, a key consideration for European consumers and regulators. Investment casting’s ability to produce lightweight parts, such as engine components and chassis elements, plays a pivotal role in helping European automakers meet fuel efficiency targets and environmental standards.

Enhanced Aesthetics and Performance

Design Freedom

Investment casting provides designers with unparalleled freedom to create components with intricate shapes and aesthetically pleasing features. This capability extends beyond functionality to include design elements that enhance the overall look and feel of vehicles. European automakers leverage investment casting to create visually striking components that set their vehicles apart in the market.

Improved Vehicle Performance

In addition to aesthetics, investment casting contributes to enhanced vehicle performance. Components such as lightweight exhaust manifolds and suspension parts can lead to improved handling, reduced noise, and optimized power output. European drivers experience smoother rides and superior vehicle performance thanks to the precision and capabilities of investment casting.

As we proceed through this guide, we will delve into the casting techniques specifically tailored for automotive parts, including the selection of alloys and design considerations. We will also explore European innovations in investment casting, highlighting the region’s commitment to pushing the boundaries of automotive manufacturing excellence.

Casting Techniques for Automotive Parts

In this section, we will explore the specialized casting techniques used for the production of automotive parts through investment casting. We will delve into the intricacies of investment casting in the automotive manufacturing sector, including considerations for alloy selection, design, and European innovations that continue to drive the industry forward.

Investment Casting in Automotive Manufacturing

Precision and Complexity

Investment casting stands out in automotive manufacturing due to its precision and ability to accommodate complex designs. The process begins with the creation of a wax or plastic pattern of the desired part. This pattern is then coated with a ceramic shell, creating a mold. Molten metal is poured into this mold, and once it solidifies, the ceramic shell is removed, leaving behind the intricately detailed casting.

Near-Net Shape

One of the key advantages of investment casting is its ability to produce near-net shape parts. This means that the castings require minimal post-casting machining, reducing production time and costs. For European automotive manufacturers, this efficiency is crucial in maintaining competitiveness.

Alloy Selection and Design Considerations

Material Selection

The choice of alloy is critical in automotive investment casting. Different alloys offer varying levels of strength, corrosion resistance, and heat resistance. European manufacturers carefully select alloys that align with the specific requirements of each automotive component. Commonly used alloys include stainless steel, aluminum, and various high-performance alloys.

Design for Investment Casting

Designing components for investment casting involves considerations such as minimizing undercuts, maintaining consistent wall thickness, and ensuring proper gating and venting. European engineers work closely with designers to optimize component designs for the investment casting process. This collaboration results in parts that are not only functional but also well-suited for efficient casting.

European Innovations in Investment Casting

Sustainable Practices

European automotive manufacturers are at the forefront of sustainable practices. They leverage investment casting to create lightweight components, reducing overall vehicle weight and improving fuel efficiency. This aligns with the region’s commitment to reducing carbon emissions and environmental impact.

Advanced Simulation

Europe embraces advanced simulation tools to optimize the investment casting process. These tools simulate the flow of molten metal and predict solidification patterns, enabling manufacturers to identify potential issues and make adjustments before casting. This results in higher-quality castings and cost savings.

Customization and Rapid Prototyping

Investment casting allows for customization and rapid prototyping, two factors highly valued in the European automotive industry. Manufacturers can quickly iterate on designs and create bespoke components to meet the evolving demands of the market.

As we conclude this guide, we will summarize the key takeaways and offer recommendations for those navigating the world of investment casting automotive parts in Europe. We will also look to the future, exploring the role of investment casting in European automotive manufacturing as it continues to evolve and innovate.

Aluminum Casting Motorcycle Engine Cover | Incredible Skills Of Casting A Bike Engine Cover

Conclusion

In this comprehensive guide, we have journeyed through the world of investment casting automotive parts and their pivotal role in the European automotive manufacturing landscape. From precision and complexity in design to weight reduction for improved efficiency, investment casting has proven to be an indispensable technique for European manufacturers aiming for excellence.

Key Takeaways and Recommendations

Let’s recap some of the key takeaways from this guide:

- Precision and Complexity: Investment casting allows for the creation of intricate and highly detailed automotive components, contributing to improved vehicle performance and reliability.

- Weight Reduction: Lightweight components produced through investment casting enhance fuel efficiency, reduce emissions, and align with Europe’s environmental standards and consumer preferences.

- Aesthetics and Performance: Investment casting not only improves functionality but also enhances the aesthetics of vehicles. Striking design elements contribute to superior vehicle performance and customer satisfaction.

- Material Selection and Design: The careful selection of alloys and thoughtful component design are critical for successful investment casting in the automotive sector. Collaboration between engineers and designers is essential to optimize designs for the casting process.

- European Innovations: European automotive manufacturers lead in sustainable practices, advanced simulation tools, and rapid prototyping, leveraging investment casting to stay at the forefront of innovation.

The Future of Investment Casting Automotive Parts in European Manufacturing

As we look to the future, investment casting will continue to be a driving force in European automotive manufacturing. Its ability to deliver precision, efficiency, and sustainability aligns perfectly with the region’s goals for the automotive industry. European manufacturers will further explore advanced alloys, sustainable practices, and customization to meet the ever-evolving demands of consumers and regulators.

Contact Information and Additional Resources

For more information, industry-specific insights, or inquiries about investment casting in the European automotive sector, please feel free to reach out to us at [Contact Information]. Additionally, we recommend exploring additional resources, such as industry associations, research publications, and trade shows, to stay updated on the latest developments in the world of investment casting automotive parts in Europe.

Thank you for joining us on this journey to explore the significance and potential of investment casting in European automotive manufacturing. We hope this guide has provided valuable insights and inspiration for your endeavors in this dynamic and vital industry.