Redefining Precision: The Role of CNC in Stainless Steel Casting

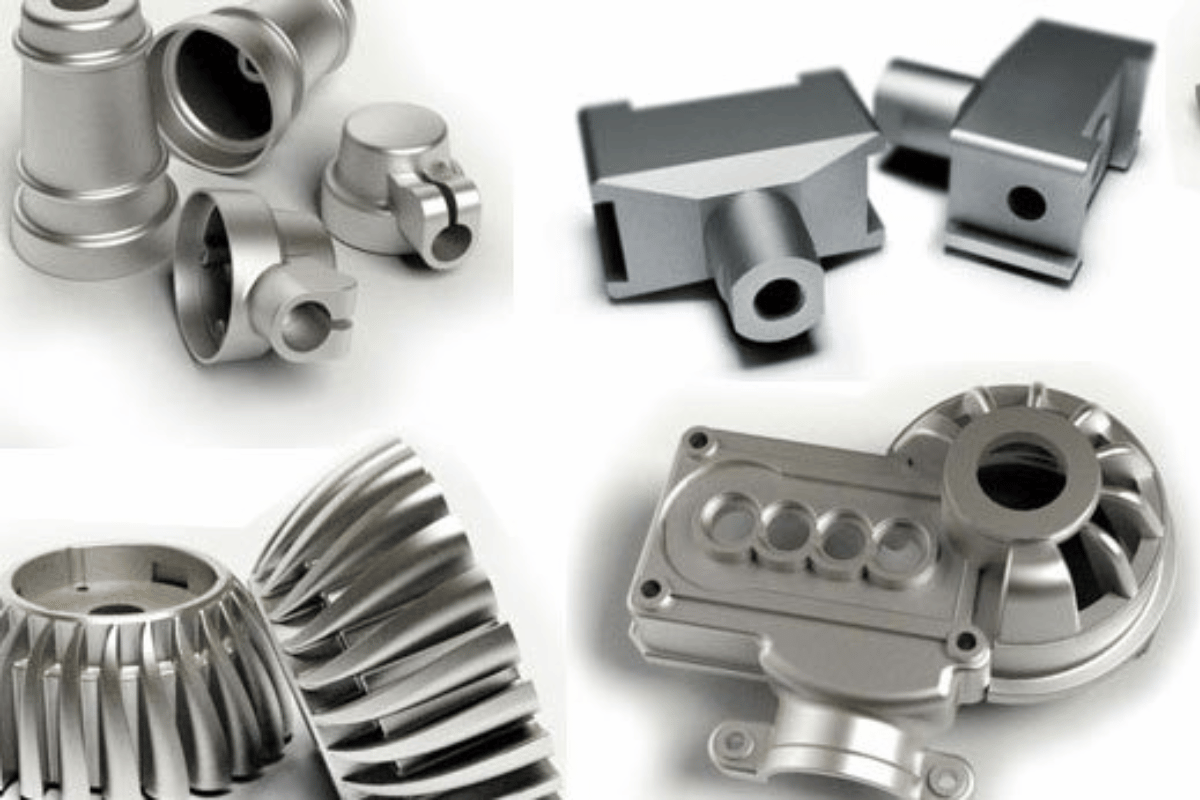

In the intricate world of stainless steel casting, precision reigns supreme. The fusion of stainless steel’s inherent strength and durability with the precision of CNC (Computer Numerical Control) technology has reshaped the landscape of manufacturing. This article embarks on a journey to unravel the symbiotic relationship between stainless steel casting and CNC precision—a marriage that has not only elevated the quality of cast components but also opened new horizons for innovation.

Overview of Stainless Steel Casting and Its Importance in Industry

Stainless steel casting stands as a cornerstone of modern industry, catering to a diverse array of applications. From aerospace to automotive, healthcare to energy, stainless steel components form the backbone of machinery, structures, and equipment. The process of stainless steel casting involves transforming molten stainless steel into intricate shapes through precision molds. This fusion of metallurgy and craftsmanship yields components that endure harsh environments and demanding conditions.

Significance of CNC Technology in Elevating Casting Quality

The arrival of CNC technology has been nothing short of revolutionary in the realm of stainless steel casting. CNC brings to the table unparalleled precision, turning intricate designs into reality with unfaltering accuracy. Every contour, every curve is meticulously carved, ensuring that the final cast component mirrors the digital blueprint. This precision extends beyond aesthetics—it directly influences the functionality, performance, and longevity of the cast parts.

As we venture further, the evolution of stainless steel casting and its harmonious coexistence with CNC technology comes into focus. The subsequent section delves into the historical development of stainless steel casting techniques and the pivotal role played by CNC in reshaping the casting landscape.

Evolution of Stainless Steel Casting and the Rise of CNC

Historical Development of Stainless Steel Casting Techniques

The roots of stainless steel casting trace back to ancient civilizations, where early craftsmen experimented with various alloys to create tools and artifacts. However, it was during the 20th century that stainless steel casting evolved into a sophisticated and widely utilized manufacturing process. The advancements in metallurgy, coupled with improved casting techniques, propelled stainless steel into the forefront of modern industry.

Emergence of CNC (Computer Numerical Control) in Manufacturing

Simultaneously, the manufacturing world was undergoing a transformation with the emergence of CNC technology. The transition from manual operations to CNC-driven precision revolutionized the production process. CNC brought with it the ability to execute complex machining operations with unparalleled accuracy, setting the stage for a new era of manufacturing excellence.

Convergence of Stainless Steel Casting Tradition with Modern CNC Precision

The convergence of stainless steel casting and CNC precision was a natural progression driven by the quest for higher quality and efficiency. Traditional casting techniques met the digital realm as CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) seamlessly integrated with casting processes. The result was a dynamic synthesis of craftsmanship and technology that unlocked new avenues for design complexity and dimensional accuracy.

As we delve deeper into the intricacies of stainless steel selection and its compatibility with CNC machining, the subsequent section explores how the choice of stainless steel alloys intersects with the demands of CNC precision in casting.

Stainless Steel Selection and CNC Machining Compatibility

Exploring Stainless Steel Alloys for Casting Applications

The selection of the right stainless steel alloy is paramount in achieving optimal casting results. Different applications demand distinct material properties, from corrosion resistance to high-temperature capabilities. Stainless steel casting companies meticulously analyze these requirements to choose alloys that align with the intended application. Alloys like austenitic, martensitic, and duplex stainless steels offer a spectrum of attributes suitable for diverse industries.

Tailoring Material Properties for Desired Performance

Stainless steel alloys can be tailored to exhibit specific mechanical and metallurgical properties. Through precise alloying and heat treatment, stainless steel casting companies can modify hardness, tensile strength, and corrosion resistance. CNC machining compatibility further guides the selection process, ensuring that the chosen alloy can be seamlessly machined to achieve intricate designs without compromising structural integrity.

Matching Stainless Steel Characteristics with CNC Machining Requirements

CNC machining imposes its own set of demands on materials. Stainless steel alloys chosen for casting must align with CNC machining requirements such as machinability, tool wear resistance, and chip control. The harmonious compatibility of the selected alloy with CNC precision is the linchpin of achieving successful machining operations. Stainless steel casting companies meticulously match alloy characteristics with CNC machining prerequisites to ensure a seamless manufacturing workflow.

With a firm understanding of the symbiotic relationship between stainless steel alloys and CNC machining, we transition to the heart of the matter—precision engineering and how CNC technology has transformed the casting process. The ensuing section delves into the realm of CAD-CAM integration, microstructure control, and achieving tight tolerances with CNC precision in stainless steel casting.

Precision Engineering: Integrating CNC in Stainless Steel Casting

CAD-CAM Integration for Optimized Stainless Steel Patterns

In the modern landscape of stainless steel casting, the journey begins with digital design. CAD software breathes life into intricate designs, capturing every contour and intricacy. This digital blueprint is seamlessly integrated with CAM, which translates the design into precise tool paths for CNC machining. The result is a machinable pattern that serves as the initial canvas for the casting process—a testament to the harmonious collaboration of design and machining precision.

Microstructure Control through CNC Machining and Solidification

The microstructure of a cast component holds the key to its mechanical properties. CNC machining extends its influence to the very core of the casting process, impacting the microstructure during both machining and solidification phases. By controlling the cooling rates and machining parameters, engineers can manipulate the microstructural characteristics of the cast stainless steel. This nuanced control enhances the mechanical attributes of the final component.

Attaining Tight Tolerances and Complex Geometries with CNC Precision

The marriage of stainless steel casting and CNC precision culminates in the creation of components with tight tolerances and intricate geometries. CNC technology deftly navigates the machining landscape, sculpting stainless steel with unparalleled accuracy. The ability to achieve close tolerances and intricate designs ensures that the final cast components align perfectly with the intended specifications, leaving little room for deviations.

As we move forward, the integration of CNC technology into the stainless steel casting workflow comes into focus. The next section elucidates the seamless unity of CNC with the casting process, starting with pattern production and culminating in CNC machining phases that yield meticulously engineered stainless steel components.

Workflow Integration: Uniting CNC with Stainless Steel Casting

Pattern Production: From Digital Design to Machinable Patterns

The journey from digital design to physical reality commences with the creation of patterns. The meticulously designed CAD model takes shape as a machinable pattern through CNC technology. Every contour, every detail is carved with precision, setting the stage for the subsequent casting process. This pattern serves as the catalyst that guides the entire manufacturing process, ensuring that the final stainless steel component mirrors the intended design.

Investment Mold Fabrication: Wax Patterns, Ceramic Shells, and CNC Prep

Patterns crafted with CNC precision are the building blocks of investment mold fabrication. These patterns are encased in ceramic shells through a series of meticulous steps. The wax pattern is coated with ceramic slurry, which solidifies to form a shell. The wax within is melted away, creating a cavity that perfectly mirrors the intricate design. CNC technology also plays a crucial role in preparing the mold for the casting process, ensuring that it is ready to receive the molten stainless steel.

CNC Machining Steps: Milling, Turning, and Hole Drilling for Stainless Steel Castings

The influence of CNC technology continues even as the casting process unfolds. The investment mold undergoes additional CNC machining steps to refine its features and dimensions. Milling and turning operations sculpt the mold to perfection, ensuring that the final stainless steel component adheres to the precision dictated by the design. Hole drilling operations add further complexity, enabling the creation of intricate features that define the component’s functionality.

As we transition to the realm of surface finish and metallurgical refinement, the subsequent section delves into the artistry of achieving impeccable surface finishes, enhancing material properties through heat treatment, and managing the effects of CNC machining on metallurgical characteristics.

Surface Finish and Metallurgical Refinement

Achieving Superb Surface Finish through CNC Techniques

Surface finish is more than just aesthetics—it plays a pivotal role in the functionality and performance of stainless steel components. CNC technology, known for its precision, extends its influence to surface refinement. Through carefully orchestrated machining operations, surfaces are rendered smooth, free from imperfections, and ready for subsequent treatments. The result is not just visual appeal, but also enhanced functionality and reduced friction.

Heat Treatment Strategies to Enhance Stainless Steel Casting Properties

The art of stainless steel casting doesn’t end with the cooling of molten metal. Heat treatment takes the stage, further refining the material properties. Through controlled heating and cooling, stainless steel casting companies tailor attributes like hardness, tensile strength, and durability to meet the demands of specific applications. CNC-enhanced stainless steel components are primed for these heat treatment strategies, their microstructures ready to be optimized.

Addressing Residual Stresses and Metallurgical Effects Introduced by CNC

The precision of CNC machining can introduce residual stresses and alter metallurgical characteristics. Stainless steel casting companies meticulously analyze these effects and implement mitigation strategies. Balancing CNC precision with metallurgical integrity is a delicate dance. Through careful monitoring and adjustments, the desired material properties are preserved, ensuring that CNC-enhanced stainless steel components possess the ideal combination of strength, durability, and precision.

With a profound understanding of surface refinement and metallurgical enhancement, we delve into the realm of quality control and assurance. The subsequent section sheds light on the real-time monitoring of CNC machining parameters, non-destructive testing (NDT) techniques, and the critical role of metrology and inspection in ensuring the final stainless steel components meet stringent standards.

Quality Control and Assurance in CNC-Enhanced Stainless Steel Casting

Real-time Monitoring of CNC Machining Parameters

Precision is the hallmark of CNC technology, and real-time monitoring ensures that this precision is upheld throughout the machining process. Sensors and monitoring systems are deployed to track crucial parameters such as tool wear, cutting forces, and temperature. Any deviations from the expected values trigger alerts, enabling immediate corrective actions. This proactive approach safeguards the quality of CNC-enhanced stainless steel components.

Non-Destructive Testing (NDT) for Defect Detection and Analysis

Ensuring the integrity of stainless steel components requires a comprehensive assessment of potential defects. Non-destructive testing (NDT) techniques play a vital role in identifying internal and surface flaws without compromising the structural integrity of the components. Methods like ultrasonic testing, radiographic inspection, and magnetic particle testing scrutinize the components for imperfections that might affect their performance.

Metrology and Inspection: Ensuring Stainless Steel Components Meet Standards

The journey from design to finished component culminates in metrology and inspection. Precision measurement techniques ascertain that every dimension, contour, and feature adheres to the intended specifications. Coordinate measuring machines (CMMs), optical measurement systems, and other advanced tools scrutinize every aspect of the components. This meticulous inspection guarantees that CNC-enhanced stainless steel components meet the stringent standards set by the industry.

As we reach the conclusion of this exploration, we reflect on the transformation of stainless steel casting through CNC precision, the implications for stainless steel industries, and the exciting prospects for manufacturing excellence in the future. The final section envisions a landscape where precision in stainless steel casting is elevated to new heights by the power of CNC technology.

How to Make Stainless Steel Parts with Investment Casting?

Conclusion

Reflecting on the Transformation of Stainless Steel Casting through CNC Precision

The journey we’ve undertaken has unveiled the transformative power of CNC technology in the realm of stainless steel casting. The convergence of craftsmanship, metallurgy, and precision machining has redefined the possibilities of what can be achieved. Every facet of the process, from digital design to final inspection, has been elevated by the touch of CNC precision, resulting in components that are not only visually stunning but also functionally superior.

Implications for Stainless Steel Industries and Manufacturing Excellence

The implications of CNC-enhanced stainless steel casting ripple through industries that rely on high-performance components. Aerospace, automotive, medical, and beyond—all benefit from the precision, durability, and consistency that CNC technology brings to stainless steel casting. Manufacturing excellence takes on a new form as CNC precision pushes the boundaries of what stainless steel components can achieve in terms of performance, reliability, and innovation.

Envisioning a Future where Precision in Stainless Steel Casting is Redefined by CNC

As we look to the horizon, the future of stainless steel casting is teeming with promise. The harmonious integration of CNC technology with stainless steel casting techniques is a harbinger of innovation yet to come. We envision a landscape where design complexity knows no bounds, where mechanical properties are honed with microscopic precision, and where stainless steel components stand as paragons of excellence in modern manufacturing.

In conclusion, the journey of stainless steel casting through the lens of CNC precision is a testament to human ingenuity, technological prowess, and the unending quest for perfection. With CNC technology as a guiding star, stainless steel casting companies forge a path towards a future where precision is not just a virtue, but a standard that sets the bar for generations to come.