In the dynamic landscape of modern manufacturing, the year 2023 emerges as a pivotal point for the stainless steel investment casting realm. This year witnesses a confluence of tradition and technology, as CNC excellence takes center stage in reshaping the future of stainless steel investment casting.

Unveiling the 2023 Advancements in Stainless Steel Investment Casting with CNC Excellence

The journey we embark upon unravels the intricate tapestry of advancements that have propelled stainless steel investment casting to unprecedented heights. At the heart of this transformation lies the fusion of stainless steel’s timeless elegance with the precision of Computer Numerical Control (CNC) technology.

Overview of Stainless Steel Investment Casting and Its Industrial Significance

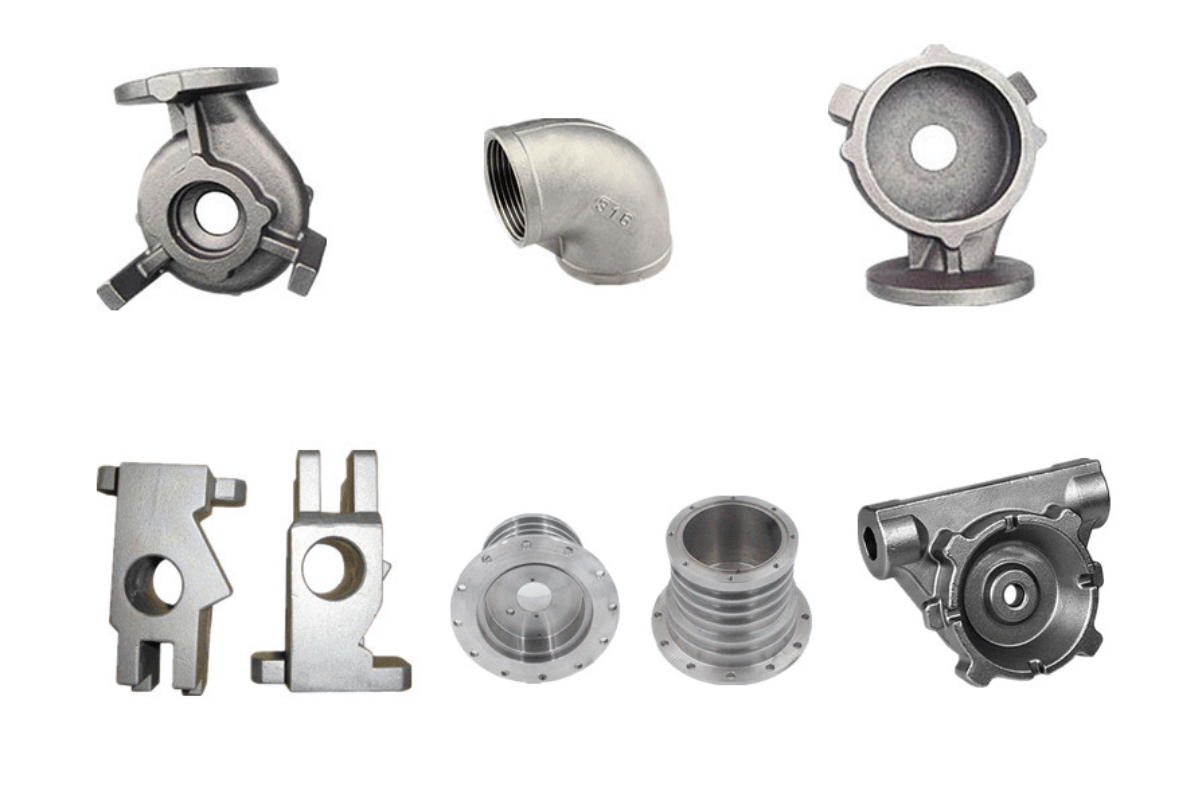

Stainless steel investment casting stands as a revered technique in the realm of metalworking. Its ability to transform intricate designs into tangible components has earned it a crucial role in various industries. From aerospace to medical equipment, stainless steel investment casting serves as the cornerstone for creating components that demand both precision and durability.

Highlighting the Role of CNC Technology in Enhancing Stainless Steel Casting

CNC technology, the epitome of precision and automation, has redefined manufacturing processes across the globe. As we delve into the world of stainless steel investment casting, it becomes evident that CNC technology introduces a new era of possibilities. This integration elevates the precision, intricacy, and overall quality of stainless steel castings.

Evolution of Stainless Steel Investment Casting and the CNC Revolution

Historical Evolution of Stainless Steel Casting Techniques

The roots of stainless steel investment casting trace back to ancient times, where skilled artisans meticulously crafted intricate objects using lost-wax casting methods. Over the centuries, this art evolved into a sophisticated science, embracing technological advancements. From the delicate creations of antiquity to the intricate components of today’s industries, stainless steel investment casting has stood the test of time.

Rise of CNC (Computer Numerical Control) in European Manufacturing

The advent of CNC technology revolutionized manufacturing processes in the 20th century. European foundries, known for their expertise in metallurgy and craftsmanship, embraced CNC as a means to enhance their capabilities. This marked a turning point where precision, consistency, and efficiency took precedence, propelling stainless steel investment casting into a new era.

Synergy between Stainless Steel Investment Casting and Modern CNC Precision

The synergy between stainless steel investment casting and modern CNC precision is where tradition meets innovation. The intricate patterns that were once handcrafted are now translated into digital designs, and CNC machines execute these designs with unparalleled accuracy. This integration offers not only consistent results but also the ability to achieve complex geometries that were once deemed challenging.

Stainless Steel Selection for Investment Casting and CNC Compatibility

Exploring Stainless Steel Alloys for Investment Casting Applications

Selecting the right stainless steel alloy is a crucial step in the investment casting process. The diverse range of stainless steel alloys available provides a palette of material properties to choose from, each tailored to specific application requirements. From corrosion resistance to high-temperature performance, these alloys offer solutions for industries ranging from aerospace to medical equipment.

Material Properties Tailoring for Desired Performance Characteristics

One of the remarkable aspects of stainless steel investment casting is the ability to tailor material properties to meet specific performance characteristics. Whether it’s enhancing strength, improving machinability, or achieving a desired surface finish, the versatility of stainless steel alloys empowers manufacturers to align the material with the intended application.

Aligning Stainless Steel Properties with CNC Machining Possibilities

The harmonious integration of stainless steel properties with CNC machining capabilities is where innovation thrives. CNC machines are equipped to handle a wide array of stainless steel alloys, from austenitic to martensitic grades. This compatibility ensures that the material’s unique properties can be harnessed to their fullest potential, resulting in components that meet exacting standards.

Precision Engineering: Integrating CNC into Stainless Steel Investment Casting

CAD-CAM Integration for Optimized Stainless Steel Patterns

The marriage of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) has revolutionized stainless steel investment casting. Engineers and designers can create intricate patterns digitally, which are then translated into machine-readable instructions. This integration ensures that the patterns are precisely reproduced, eliminating the variability inherent in manual processes.

Microstructure Control through CNC Machining and Solidification

CNC machining plays a pivotal role in achieving precise microstructures within stainless steel castings. By controlling machining parameters and solidification conditions, manufacturers can influence the material’s grain structure, which has a direct impact on mechanical properties. CNC-enhanced solidification leads to more uniform and desirable material characteristics.

Achieving Complex Geometries and Close Tolerances with CNC Precision

Stainless steel investment casting often involves intricate geometries and tight tolerances. CNC machines excel at producing these complex shapes with unparalleled accuracy. The ability to work at micron-level precision ensures that every feature of the casting meets the specified dimensions, resulting in components that fit seamlessly within assemblies.

Workflow Harmony: Merging CNC with Stainless Steel Investment Casting

Transitioning from Digital Designs to Machinable Investment Patterns

The journey from digital designs to physical investment patterns marks a crucial phase in stainless steel investment casting. The CAD models, rich with design intent, are transformed into machinable patterns through CNC technology. This step ensures that the intricacies captured in the digital realm are faithfully recreated in the tangible patterns used for mold creation.

Investment Mold Fabrication: Wax Patterns, Ceramic Shells, and CNC Preparation

The investment casting process involves creating molds around the machinable patterns. Wax patterns are initially assembled and coated with ceramic shells to form the molds. CNC technology further aids in this stage by preparing the mold components with precision. This meticulous preparation contributes to the accurate transfer of the pattern’s geometry onto the final casting.

CNC Machining Phases: Milling, Turning, and Hole Drilling for Stainless Steel Castings

CNC’s prowess extends to the machining of the stainless steel castings themselves. Milling operations shape the casting’s exterior, while turning processes refine cylindrical features. Hole drilling, a common requirement in many castings, is executed with high precision through CNC techniques. This integration ensures that the casting’s exterior and interior align seamlessly with the original design.

Surface Refinement and Metallurgical Enhancement

Attaining Superior Surface Finish via CNC Techniques

Surface finish plays a pivotal role in the aesthetics, functionality, and overall quality of stainless steel investment castings. CNC technology introduces an elevated level of precision to surface refinement. Through carefully programmed tool paths and advanced cutting strategies, CNC machining achieves remarkably smooth surfaces that enhance both visual appeal and performance. This attention to surface quality is vital, especially in applications where the casting’s appearance is a critical aspect.

Heat Treatment Strategies to Optimize Stainless Steel Casting Properties

Beyond surface finish, the metallurgical properties of stainless steel castings are also subject to optimization through CNC-driven processes. Heat treatment, a controlled heating and cooling process, is employed to modify the material’s mechanical properties. CNC’s role lies in ensuring uniform heating and precise cooling, thereby preventing distortion and maintaining dimensional accuracy. This synergy between CNC and heat treatment enhances the casting’s overall integrity.

Addressing CNC-Induced Residual Stresses and Metallurgical Effects

CNC machining, while enhancing stainless steel casting precision, can introduce residual stresses due to the material removal process. These stresses may impact the casting’s structural integrity and performance. However, CNC technology also offers the means to mitigate these effects. By strategically planning machining sequences, optimizing tool paths, and employing appropriate cooling techniques, manufacturers can minimize residual stresses and uphold the casting’s mechanical properties.

Stainless steel ring casting process | CF Jewelry

Conclusion

Reflecting on the Advancements in Stainless Steel Investment Casting through CNC Excellence

The fusion of stainless steel investment casting with CNC technology has ushered in a new era of precision, quality, and efficiency. This synergy leverages the strengths of both fields, yielding castings that meet the highest standards of modern industries. As we conclude this exploration, it’s evident that CNC’s role in stainless steel investment casting goes beyond mere machining; it’s a catalyst for innovation, transformation, and excellence.

Implications for Stainless Steel Industries and Global Manufacturing

The advancements brought about by CNC-enhanced stainless steel investment casting hold immense implications for industries that rely on stainless steel components. Sectors ranging from aerospace and automotive to medical devices and energy benefit from the superior quality, tighter tolerances, and intricate geometries achievable through CNC. Moreover, these innovations contribute to the broader landscape of global manufacturing, setting new benchmarks for quality and performance.

Envisioning a Future where CNC Elevates Stainless Steel Investment Casting to New Heights

The journey of stainless steel investment casting is intertwined with the evolution of CNC technology. Looking ahead, the trajectory promises even greater achievements. As CNC capabilities continue to expand, the potential for more intricate designs, higher precision, and enhanced material properties becomes evident. The partnership between CNC and stainless steel investment casting is an ongoing story of innovation, resilience, and the pursuit of excellence.