Navigating the Landscape of CNC Innovations in Stainless Steel Casting Foundries (2023)

In the ever-evolving realm of modern manufacturing, precision and quality have become synonymous with success. Amid this dynamic landscape, stainless steel casting has emerged as a cornerstone, offering a seamless blend of strength, durability, and intricate design possibilities. At the heart of this transformative process lies the stainless steel casting foundry, where tradition and innovation intersect to shape the future of production.

Overview of Stainless Steel Casting and Its Impact on Modern Manufacturing

Stainless steel casting stands as a testament to the marriage of metallurgy and craftsmanship. This versatile process involves the formation of complex components through the meticulous pouring of molten stainless steel into intricately designed molds. The resulting products find their applications across industries as diverse as aerospace, automotive, and healthcare. The ability to achieve unparalleled strength-to-weight ratios and intricate geometries positions stainless steel casting as a pioneer in the world of precision manufacturing.

Emphasizing the Role of CNC Technology in Shaping Casting Quality

In this era of precision, CNC (Computer Numerical Control) technology stands as a harbinger of transformation. It is the driving force behind the revolution taking place within stainless steel casting foundries. The integration of CNC technology injects a new level of precision, consistency, and efficiency into the casting process. From design inception to final inspection, CNC innovations are reshaping the landscape, elevating the quality and functionality of stainless steel components.

As we delve into the evolution of stainless steel casting techniques and the infusion of CNC technology, we embark on a journey that uncovers the historical roots and contemporary advancements that shape the casting foundry of today.

Evolution of Stainless Steel Casting Techniques and the CNC Revolution

Tracing the Historical Development of Stainless Steel Casting Methods

The origins of stainless steel casting date back centuries, characterized by a fusion of artistry and metallurgical knowledge. Traditional techniques involved meticulous craftsmanship and labor-intensive processes, resulting in components that were often limited in complexity and precision. However, the innate properties of stainless steel—resistance to corrosion, heat, and wear—captured the imagination of manufacturers and propelled the evolution of casting techniques.

Emergence of CNC (Computer Numerical Control) in European Manufacturing

The advent of CNC technology marked a seismic shift in manufacturing paradigms. With the precision and automation it brought, CNC technology swiftly found its way into stainless steel casting foundries, revolutionizing every facet of the process. European manufacturing, known for its dedication to quality and innovation, played a pivotal role in the integration of CNC into casting techniques. This convergence unleashed a new era of possibilities, where stainless steel casting transcended limitations and embraced the realm of precision engineering.

Confluence of Traditional Casting with Precise CNC Machining

The evolution of stainless steel casting has never been a tale of replacement, but rather a story of integration. Traditional casting techniques, with their artful craftsmanship, meld seamlessly with CNC precision. This synergy results in components that not only retain the exceptional material properties of stainless steel but also exhibit levels of accuracy and complexity that were once deemed unattainable. The CNC revolution has breathed new life into the traditional craft, pushing boundaries and setting benchmarks for quality.

As we delve deeper into the realm of stainless steel casting alloys and their harmonious interaction with CNC machining, we uncover the intricate dance between material science and technological innovation that underpins the casting foundry of today.

Stainless Steel Alloys: Selection and Synergy with CNC Machining

Exploring Stainless Steel Alloys for Optimal Investment Casting Performance

The choice of stainless steel alloys is a pivotal decision that influences the performance and durability of the final cast components. With a plethora of alloys available, each with distinct properties, selecting the optimal one for a given application requires a keen understanding of material science and engineering. Stainless steel casting foundries meticulously assess factors such as corrosion resistance, mechanical strength, and thermal stability to ensure the chosen alloy aligns with the intended use.

Tailoring Material Properties to Fulfill Specific Application Requirements

The synergy between stainless steel alloys and CNC machining lies in their shared mission—to cater to specific application demands. The ability to tailor material properties to fulfill these requirements is where the true magic happens. By adjusting alloy composition and processing parameters, manufacturers can fine-tune characteristics such as hardness, ductility, and impact resistance. This tailoring ensures that the cast components possess the ideal combination of attributes to excel in their designated roles.

Aligning Stainless Steel Characteristics with CNC Machining Capabilities

Stainless steel alloys selected for casting must also be aligned with the capabilities of CNC machining. The interaction between the material and CNC tools, such as drills and mills, plays a crucial role in achieving the desired precision and finish. Compatibility between the alloy’s machinability and the CNC process ensures that intricate geometries are carved with precision, complex designs are executed flawlessly, and tight tolerances are maintained.

As we venture further into the marriage of CNC technology and stainless steel casting, we uncover the profound relationship between alloy selection and CNC machining, a partnership that forms the foundation for precision engineering in the casting foundry.

Precision Engineering: Exploring the Marriage of CNC and Stainless Steel Casting

CAD-CAM Integration for Enhanced Stainless Steel Casting Patterns

The marriage of CNC technology and stainless steel casting begins with the digital realm. Computer-Aided Design (CAD) software transforms concepts into intricate patterns that serve as the blueprint for casting. This digital representation seamlessly integrates with Computer-Aided Manufacturing (CAM) software, which translates the design into machine-readable code. This integration ensures that every curve, contour, and feature is faithfully reproduced in the final stainless steel component.

Microstructure Control through CNC Machining and Solidification

CNC precision extends its influence beyond the digital realm and into the very heart of the casting process. The control it offers over machining parameters directly affects the microstructure of the cast stainless steel. By optimizing cooling rates and solidification processes, CNC technology contributes to the formation of finer and more uniform grain structures. This, in turn, enhances mechanical properties and contributes to the overall integrity of the cast component.

Achieving Intricate Geometries and Close Tolerances with CNC Precision

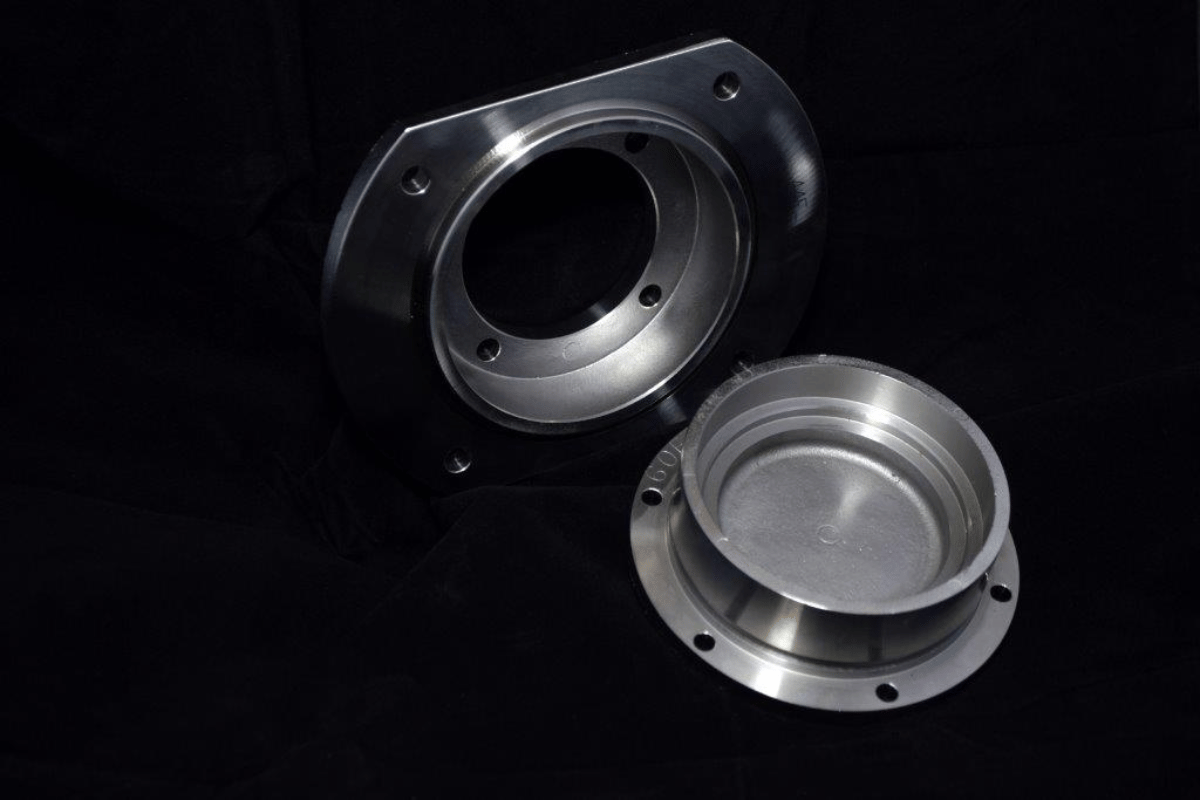

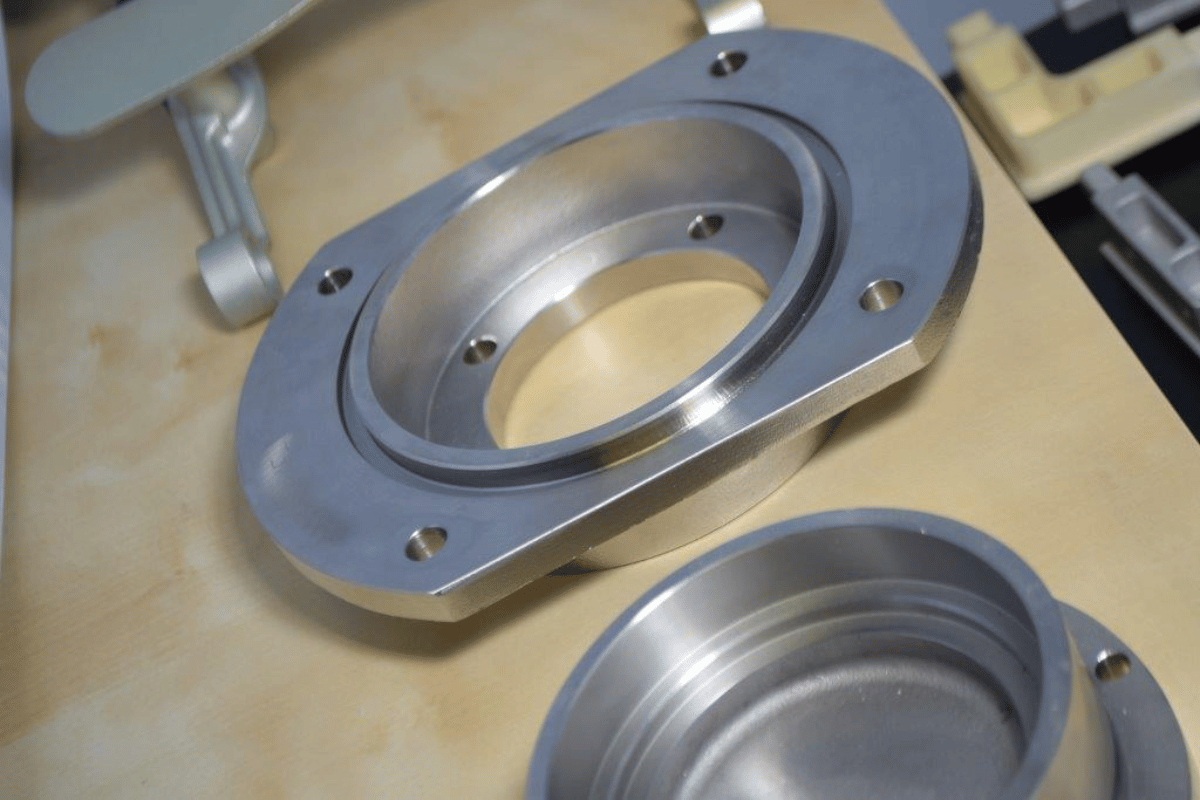

One of the hallmarks of CNC-enhanced stainless steel casting is its ability to create components with intricate geometries and tight tolerances. Traditional casting methods often struggled to replicate complex shapes and maintain stringent tolerances. CNC machining, however, excels in this regard, carving out designs with meticulous precision. This capability empowers designers to envision innovative shapes that were once deemed impractical, opening doors to unprecedented possibilities.

As we delve into the heart of the casting process, the fusion of CNC technology and stainless steel casting comes to life, showcasing the seamless transition from digital design to physical patterns, and the intricate dance between machining and solidification that defines the quality and performance of the final stainless steel component.

Workflow Integration: Elevating Stainless Steel Casting through CNC

Transitioning from Digital Designs to Machinable Investment Patterns

The transformation from digital designs to tangible investment patterns marks a crucial juncture in the stainless steel casting process. The precision and fidelity of CNC machining ensure that every contour and detail of the digital design is faithfully translated into the physical pattern. This accuracy reduces the need for manual adjustments and iterations, streamlining the production workflow and enhancing overall efficiency.

Investment Mold Crafting: Wax Patterns, Ceramic Shells, and CNC Preparation

The investment casting process involves the creation of molds that encapsulate the wax patterns—a process that now benefits from CNC technology. CNC machining is employed to craft precise wax patterns that form the basis for the ceramic shell molds. The resulting molds not only exhibit superior dimensional accuracy but also ensure consistent shell thickness. This synergy between CNC and investment casting techniques guarantees the reproducibility of intricate components.

CNC Machining Stages: Milling, Turning, and Hole Drilling for Stainless Steel Castings

As the casting process unfolds, CNC technology continues to play a pivotal role. CNC machining stages encompass milling, turning, and hole drilling, each contributing to the final form of the stainless steel castings. Milling and turning processes shape the component’s external and internal features with meticulous precision. Hole drilling, often requiring exact alignment and depth, is executed flawlessly thanks to CNC-controlled equipment.

As we navigate through the intricate dance of transitioning from digital designs to investment patterns and the subsequent CNC machining stages, we witness the seamless integration of technologies that define the modern stainless steel casting foundry—a realm where precision and innovation coalesce to shape the components of tomorrow.

Surface Refinement and Metallurgical Enhancement

Achieving Superlative Surface Finish through CNC Techniques

The surface finish of stainless steel castings holds significant importance, impacting aesthetics, functionality, and performance. CNC technology’s influence extends to this realm as well, offering techniques to achieve superlative surface finishes. By carefully controlling machining parameters, tool paths, and cutting speeds, manufacturers can achieve smooth surfaces with minimal tool marks. This level of precision elevates the overall appearance and functionality of the final components.

Heat Treatment Strategies to Optimize Stainless Steel Casting Properties

Beyond surface finish, the mechanical properties of stainless steel castings can be optimized through heat treatment—a process that can be seamlessly integrated with CNC machining. Heat treatment strategies such as annealing, quenching, and tempering are executed with precision, ensuring that the cast components attain the desired hardness, strength, and ductility. This combination of CNC and heat treatment contributes to the exceptional performance of the finished parts.

Addressing CNC-Induced Residual Stresses and Metallurgical Effects

While CNC machining enhances the precision of stainless steel castings, it can also introduce residual stresses and metallurgical effects. These effects can impact the mechanical properties and dimensional stability of the components. Through careful analysis and simulation, manufacturers can mitigate these challenges. CNC’s ability to execute controlled material removal and precise machining paths plays a vital role in minimizing adverse effects and ensuring consistent quality.

As we delve into the realm of surface refinement, heat treatment, and the careful management of residual stresses, we uncover how CNC technology’s meticulous control transforms stainless steel castings from raw forms into components of exceptional quality, ready to excel in demanding applications.

Quality Assurance in CNC-Enhanced Stainless Steel Casting

Real-time Monitoring of CNC Machining Parameters for Precision

The pursuit of precision and quality in stainless steel casting is underpinned by real-time monitoring of CNC machining parameters. Advanced sensors and monitoring systems provide insights into the machining process, enabling operators to make immediate adjustments if deviations occur. This proactive approach ensures that each component adheres to the desired specifications, minimizing variations and enhancing overall consistency.

Non-Destructive Testing (NDT) Techniques for Detecting Flaws

Quality assurance extends beyond machining to the detection of flaws and defects. Non-destructive testing (NDT) techniques, such as ultrasonic testing and radiographic inspection, are employed to identify hidden irregularities within the stainless steel castings. The integration of NDT with CNC machining ensures that components not only meet surface finish standards but also possess integrity and reliability beneath the surface.

Metrology and Inspection: Ensuring Stainless Steel Meets Rigorous Standards

Metrology and inspection form the final line of defense in ensuring the quality of CNC-enhanced stainless steel castings. Precise measurement technologies, such as coordinate measuring machines (CMMs) and optical scanners, meticulously assess dimensional accuracy, geometrical tolerances, and surface characteristics. This rigorous scrutiny guarantees that each component leaving the foundry meets or exceeds industry standards.

As we conclude our exploration of quality assurance, we recognize the pivotal role played by real-time monitoring, NDT techniques, and thorough metrology in safeguarding the integrity of CNC-enhanced stainless steel castings. This commitment to quality underlines the dedication of modern casting foundries to deliver components of unwavering excellence.

Stainless Steel Foundry China,303 304 310 316L 347 410 416 420F 431 440C 440F 442 PH15-5 PH17-4 Cast

Conclusion

In the landscape of stainless steel casting foundries, the integration of CNC technology has ushered in a new era of precision, quality, and innovation. From the inception of digital designs to the meticulous crafting of investment patterns, from the precision machining stages to the final quality assurance measures, CNC has become the driving force behind the redefinition of stainless steel casting excellence.

Through this journey, we’ve unveiled the power of CNC technology in elevating stainless steel casting to new heights. We’ve explored the synergy between stainless steel alloys and CNC machining, witnessing how the harmonious interplay of materials and precision engineering leads to components that meet the most demanding applications.

As we reflect on the transformation of stainless steel casting through CNC precision, we acknowledge its far-reaching implications. Industries across the spectrum, from aerospace to automotive, from energy to healthcare, stand to benefit from the unmatched quality and reliability that CNC-enhanced stainless steel casting brings.

This union of tradition and technology, of centuries-old casting practices and cutting-edge CNC precision, has reshaped the narrative of stainless steel casting foundries. The journey is far from over. As technology continues to advance and new horizons emerge, the future holds untold possibilities for further refining the art of casting through the mastery of CNC precision.